Custom EVA Foam Inserts: Design Guide for Tool Boxes & Case Interiors

Designing Custom EVA Foam Inserts for Cases and Tool Boxes

If you carry calibrated instruments, power tools, or service kits, you already know the failure modes. Tools rub, edges chip, and small parts migrate to the bottom of the case. Custom EVA Foam inserts solve that by controlling position, adding impact protection, and making organization visible at a glance.

في Damao Tech, most insert projects start with one question. What needs to stay protected, and what needs to stay fast to access? The right foam layout answers both.

Why Choose EVA Foam for Protective Inserts?

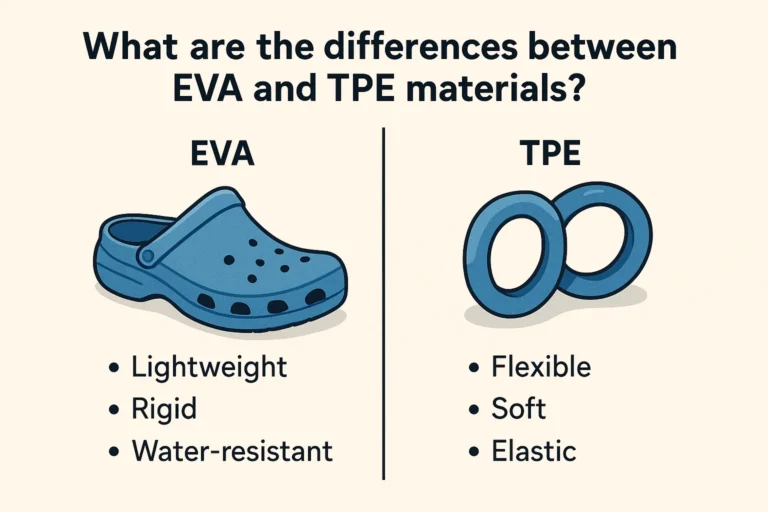

EVA (ethylene-vinyl acetate) is commonly used for protective packaging and gear storage because it is closed cell, resilient, and easy to fabricate in different colors and hardness options.

From a user perspective, EVA Foam tends to work well when you need:

- Clean handling: Closed cell foams are typically easier to wipe clean than open cell foams.

- Durable cushioning: Resilient foam helps reduce impact transfer during transport.

- A professional layout: Two tone “shadow” styles help with tool control and quick checks.

For more material options and conversion methods, see our EVA overview page: رغوة EVA

Start With Use Case Requirements (Not With Cutting Method)

Before CAD or cutting, define the job the insert must do. Damao Tech typically asks customers for these inputs because they determine design geometry:

- Item list

- Tools, chargers, bits, fasteners, batteries, gauges, accessories

- Handling mode

- Carry-on, jobsite truck, shipping carton, flight case

- Risk factors

- Drops, vibration, oil exposure, humidity, dust

- Workflow

- What gets used daily

- What must be counted back in

This prevents the most common mistake. Creating a layout that looks good but slows work down.

Layout and Pocket Design That Improves Usability

A foam insert should reduce search time and repack time. Focus on features that affect hands on use.

Finger pulls and extraction clearance

Design finger pulls for anything that sits flush. If a pocket is too tight and has no relief, users pry tools out and tear foam edges.

Common approaches:

- Half moon finger pull at one edge

- Slot pull through for long tools

- Step pocket (deep plus shallow areas) so fingertips can grab

Two tone shadow foam for tool control

Two tone رغوة EVA inserts make missing tools obvious because the base layer contrasts with the top color. This is useful in maintenance and field service kits where “nothing left behind” matters.

Orientation and labels

If different tools feel similar, visual cues prevent mix ups:

- Etched or printed labels on the foam surface (where the process supports it)

- Simple icon marks near pockets for left to right packing order

Material Selection: Density and Hardness Matter

Different foams can all be cut into shapes. Real performance depends on selecting the right grade for the load and handling conditions.

When customers ask Damao Tech what to choose, the practical rule is:

- Heavier tools need foam that resists bottoming out.

- Delicate items need consistent support that does not compress permanently.

If you already have a spec, Damao Tech can match it. If not, start by sharing:

- Tool weight range

- Drop risk

- Target insert thickness

- Whether you need a firm snap fit or a gentle cradle

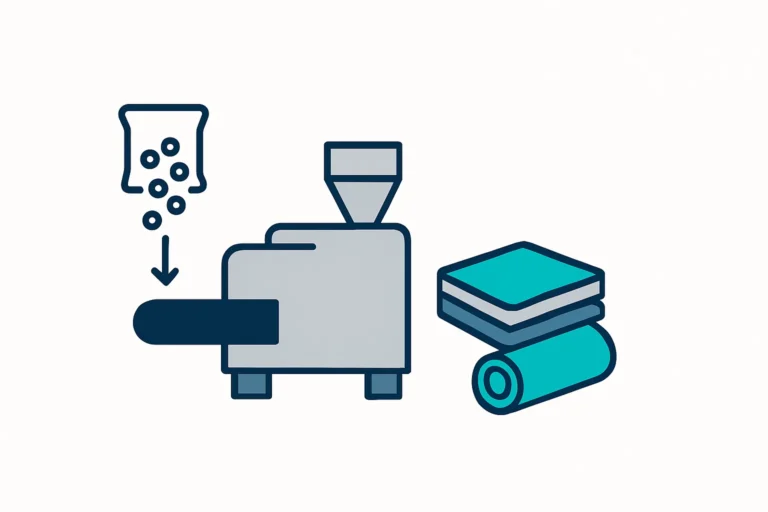

Fabrication Methods: CNC Routing vs Die Cutting

Two common production routes are die cutting و CNC routing.

Die cutting (good for simpler shapes and volume)

Choose die cutting when:

- The geometry is mostly 2D cut through profiles

- Volumes justify tooling

- You need fast cycle times per part

Tradeoff. It is not ideal for complex 3D pocket depths unless you build multi layer stacks.

CNC routing (good for complex pockets and prototypes)

Choose CNC routing when:

- You need pockets with defined depth steps

- Shapes change often

- You are prototyping or running mixed SKUs

Many real projects combine methods. For example, Damao Tech may propose CNC for first articles, then switch to die cutting for stable, higher volume programs.

Multi Layer Foam Inserts (When One Layer Is Not Enough)

A single foam slab can work for basic storage. Multi layer designs solve tougher problems:

- Top layer

- Precise cutouts for tool retention

- Middle layer

- Depth control for tall items

- Bottom layer

- Impact buffer and a clean base

Multi layer stacks also let you:

- Use different foam grades per layer

- Add PSA backing or laminated layers for assembly speed

Fit and “Rattle Control” Acceptance Checks

A foam insert is successful when it controls movement without forcing users to fight it.

Acceptance checks to run before production:

- Shake test: Close the case and shake in multiple orientations. Listen for movement.

- Drop logic: Identify what hits first if the case drops on an edge.

- Access time: Can a user remove and return the top 3 tools quickly?

- Edge durability: Thin walls between pockets tear first. Widen these areas where possible.

What to Send for a Quote

To quote custom EVA Foam inserts, Damao Tech can work from:

- CAD files (DXF, DWG, STEP)

- A dimensioned sketch plus tool list

- Photos with a scale reference (for early estimating)

If you do not have drawings, start with the case internal dimensions and a tool inventory.

الأسئلة الشائعة (FAQ)

1) Are EVA Foam inserts better than pluck foam?

Pluck foam is quick for temporary setups, but it often loses shape with repeated use. Custom cut EVA Foam provides cleaner organization and more consistent fit.

2) Can you make two tone shadow foam inserts for tool control?

Yes. Two layer color stacks are a common way to make missing tools visible during audits and end of shift checks.

3) Should I choose CNC routing or die cutting?

CNC routing is often preferred for prototypes and stepped pockets. Die cutting is often preferred for simpler shapes and higher volumes.

4) What information do you need to start design?

Case model or internal dimensions, the list of items, and how the kit is used.

5) Can the insert include adhesive backing or laminated layers?

Yes. Many EVA Foam builds use laminated stacks or PSA backed sheets depending on assembly needs.

Request a Quote From Damao Tech

If you are building a tool control kit, service case, or protective packaging that has to survive real handling, Damao Tech can help you design and manufacture custom EVA Foam inserts that match your workflow.

Send your drawing or requirements for a fast quote: رغوة EVA