Advanced Casting Film Machine

High-automation, energy-efficient, and flexible solution for producing premium casting films across industries.

Request a QuoteWhy Choose Our Casting Film Machine?

Engineered to deliver tangible advantages, enhancing your production capabilities and boosting your bottom line.

High Degree of Automation

Siemens PLC and touchscreen control keep production stable while reducing operator workload.

Energy Saving & Eco-Friendly

Optimized heating zones and tension control deliver high output with minimal energy consumption.

Flexible & Diversified

Adapts to different materials, widths, and thicknesses for packaging, agriculture, and industrial films.

Stable & Reliable

Optimized mechanical design with high-quality components reduces maintenance and downtime.

Casting Film Production Flow

From feeding to winding, every stage is automated for smooth, repeatable output.

Extrusion & Casting

Precise melt extrusion feeds the casting roll with uniform thickness control.

Quenching & Cooling

High-efficiency chill rollers rapidly cool film to lock in clarity and strength.

Stretching & Tensioning

Closed-loop tension systems stabilize film width and thickness during line speed changes.

Edge Trim & Winding

Automatic slitting, trim recovery, and servo winding deliver neat, consistent rolls.

Product Features

Smart Control Backbone

Siemens PLC coordinates every zone with intuitive touchscreen control, keeping film thickness, tension, and speed locked to your recipe.

- Closed-loop tension feedback for wrinkle-free rolls.

- Recipe storage for rapid product changeovers.

- Alarm and diagnostics to minimize downtime.

Quality-Focused Hardware

Robust chill rolls, precision embossing, and optimized air knives ensure optical clarity and consistent mechanical properties.

- Embossing unit with stable tension control.

- Energy-efficient heating zones reduce power draw.

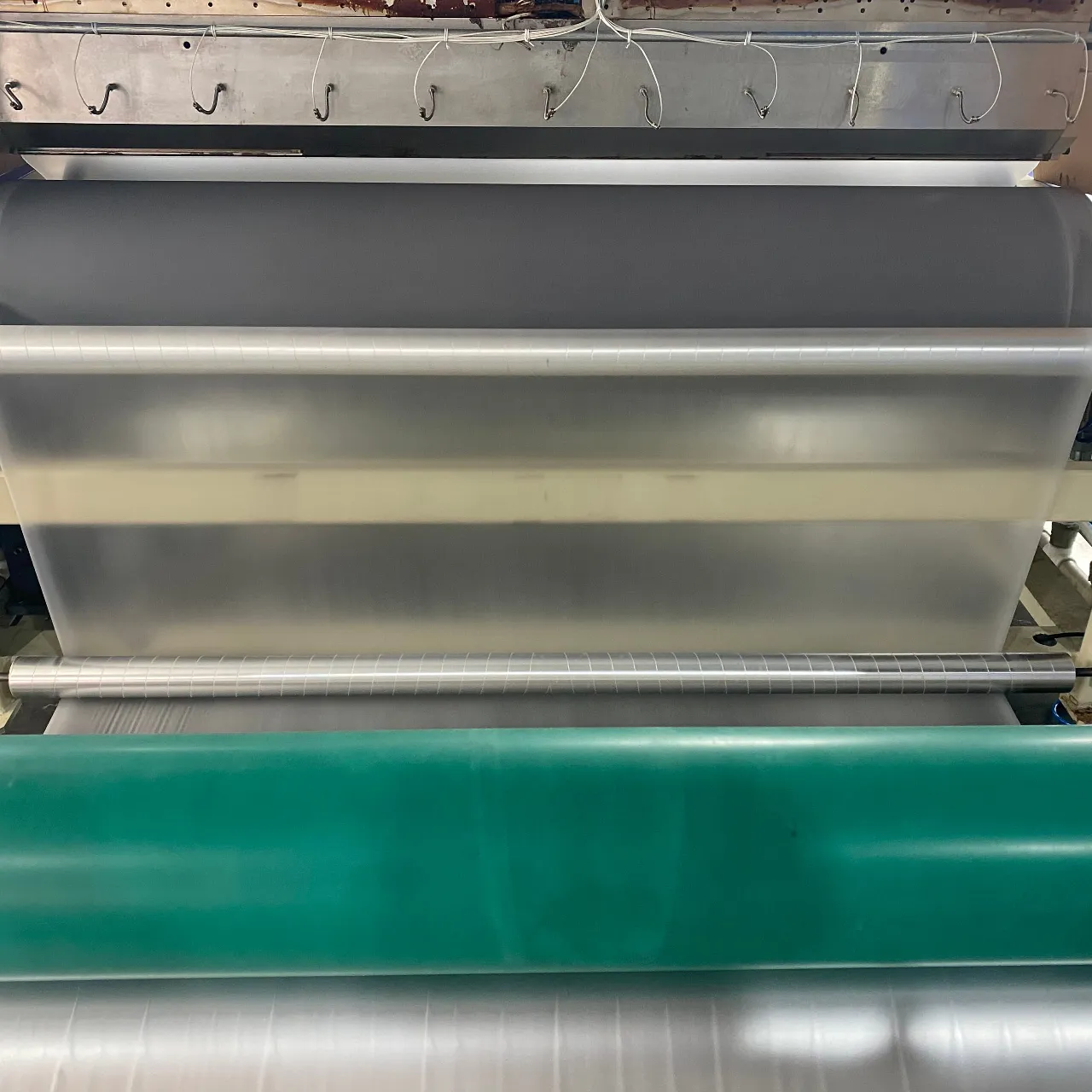

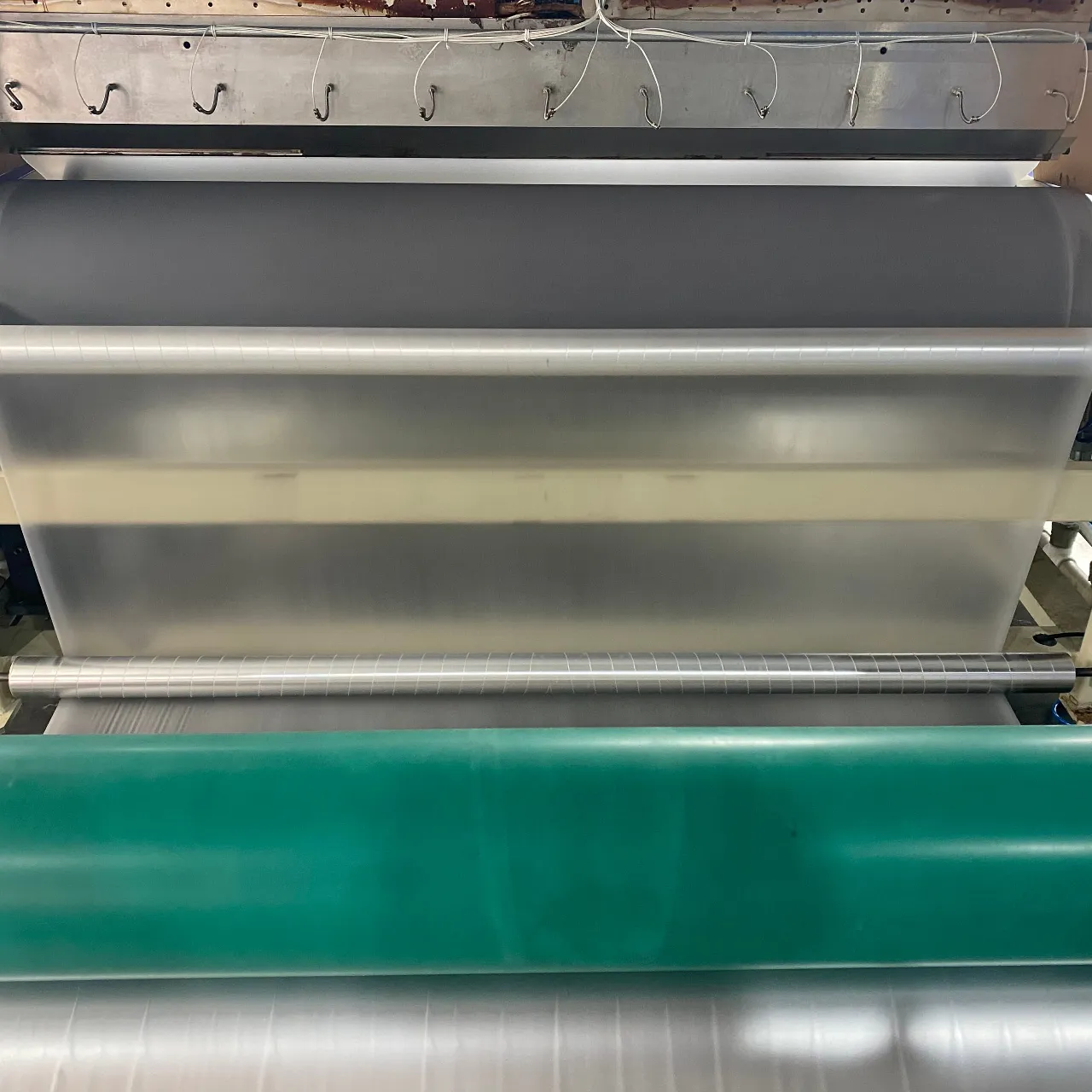

Explore the Casting Line

High-resolution views of the extrusion, casting, and winding zones to help you visualize the full production flow.

Technical Specifications

| Model and specification | 1600 | 1800 | 2000 | 2200 | 2400 | 2700 |

|---|---|---|---|---|---|---|

| Screw diameter (mm) | φ110 | |||||

| Length-diameter ratio | 36:1 | |||||

| Main motor power (Kw) | 30-110 | |||||

| Electrical heating (Kw) | 63 | 66 | 70 | 73 | 77 | 85 |

| Maximal extruder output (kg/h) | 100-180 | |||||

| Maximal width of product (mm) | 1400 | 1600 | 1800 | 2000 | 2200 | 2500 |

| Product thickness (mm) | 0.01-0.15 | |||||

| Production efficiency (m/min) | 10-100 | |||||

| Specifications of embossing roller (mm) | φ370*1500 | φ370*1700 | φ370×1900 | φ370*2100 | φ370×2300 | φ370×2600 |

| Embossing motor power (Kw) | 3 | |||||

| Tracting & wind-up roll specification (mm) | φ210 or φ270×1500 | φ210 or φ270×1700 | φ210 or φ270×1900 | φ210 or φ270*2100 | φ210 or φ270*2300 | φ210 or φ270*2600 |

| Pulling & wind-up motor power (Kw) | 1.5 | |||||

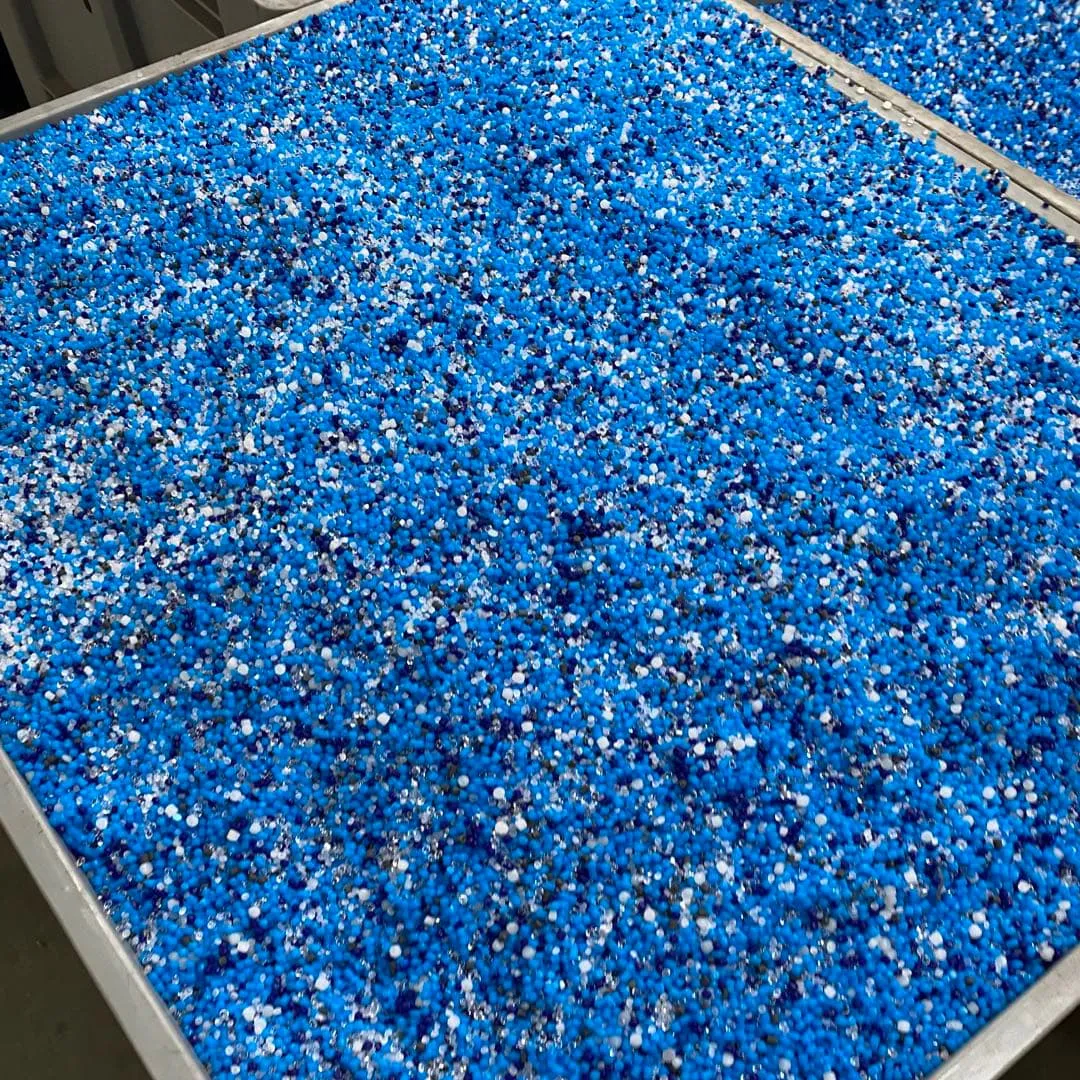

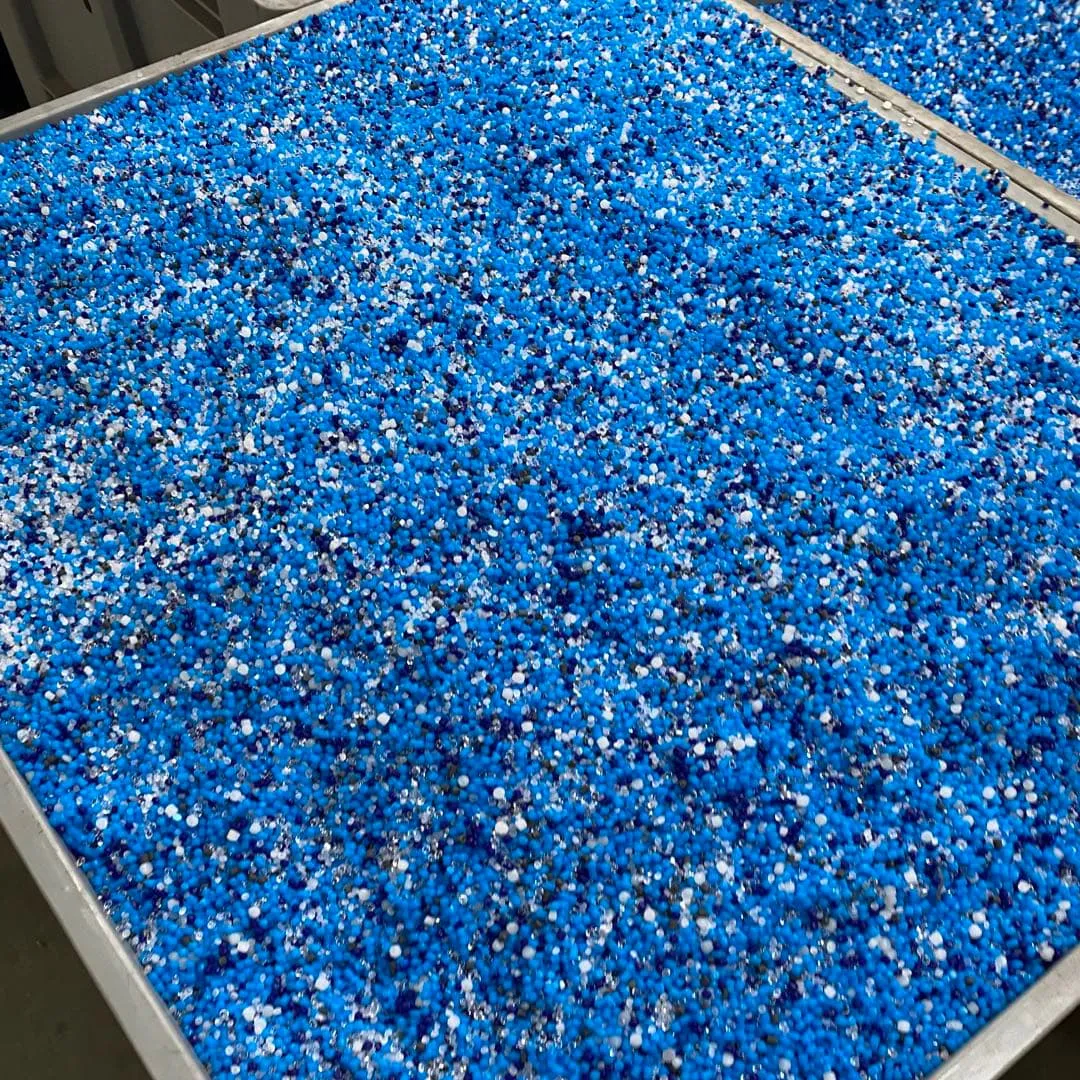

| Edge-trim reclamation | Pelletizer (wind blowing type) | |||||

| Cooling method | Circulating water cooling system | |||||

Product Applications

The films produced by our casting film machine are widely used in multiple industries.

Packaging Industry

Ideal for food, medicine, and daily necessities packaging to protect and preserve products.

Agricultural Field

Used for farmland and greenhouse covering to regulate soil temperature and humidity.

Industrial Applications

Suitable for plastic bags, sheets, and waterproof materials where durability matters.

Medical Industry

Produces medical films, dressings, and device packaging to ensure health and safety.

Printing Industry

Excellent base film for high-quality printing of packaging and advertising materials.

Get a Customized Casting Line

Tell us about your target film thickness, material, and roll width. We’ll configure the casting solution that fits your output and quality goals.