EVA Foam Manufacturer & Custom Solutions

From material to manufacturing—sheets, rolls, die-cutting, lamination, and thermoforming. Built to your drawing and performance specs with fast lead times and global shipping.

Upload drawings or specs (PDF/DWG/STEP).

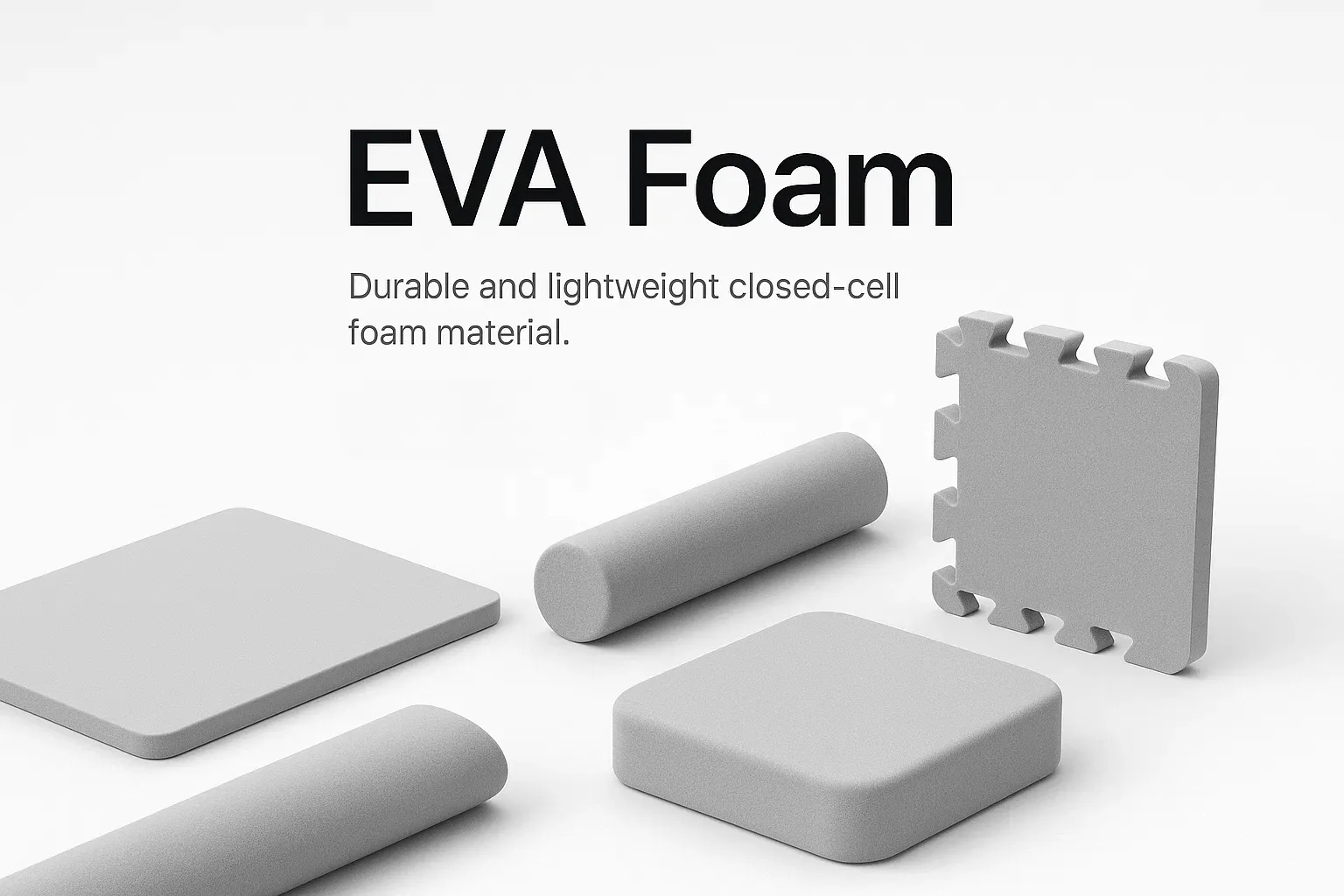

Why Choose EVA Foam for Your Project

EVA (Ethylene‑Vinyl Acetate) is a closed‑cell, lightweight, and resilient foam used across packaging, footwear, automotive, and consumer goods. It balances cushioning, flexibility, and durability with excellent water resistance.

Compared with many alternatives, EVA is easier to fabricate (cutting, thermoforming, sanding), maintains performance in humid environments, and supports broad appearance and functional options.

Core Advantages of EVA Foam Material

- Lightweight impact absorption: Ideal for protective packaging and wearables.

- Closed‑cell water resistance: Repels moisture and is easy to clean.

- Easy fabrication: Cutting, thermoforming, sanding, coating, and printing.

- Flexible aesthetics: Color, texture, hardness, and density options.

- Safe formulations: Low‑odor, non‑toxic options available.

- Cost‑effective supply: Suited to scale production and consistent availability.

Product Formats & Customization

Supply Forms

Sheets and rolls; die‑cut/kiss‑cut parts; pre‑laminated assemblies.

Thickness

Broad range; cut‑to‑size sheets or roll widths per spec.

Density & Hardness

Multiple grades; Shore A and rebound/compression‑set options.

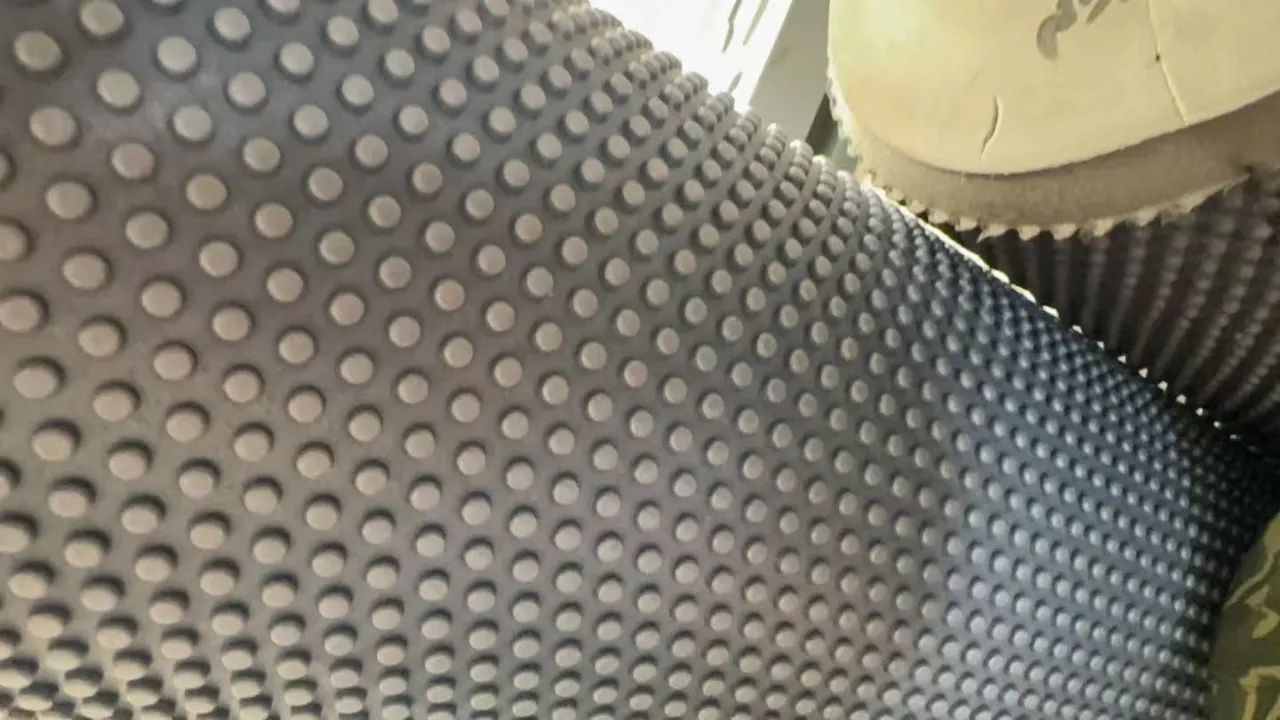

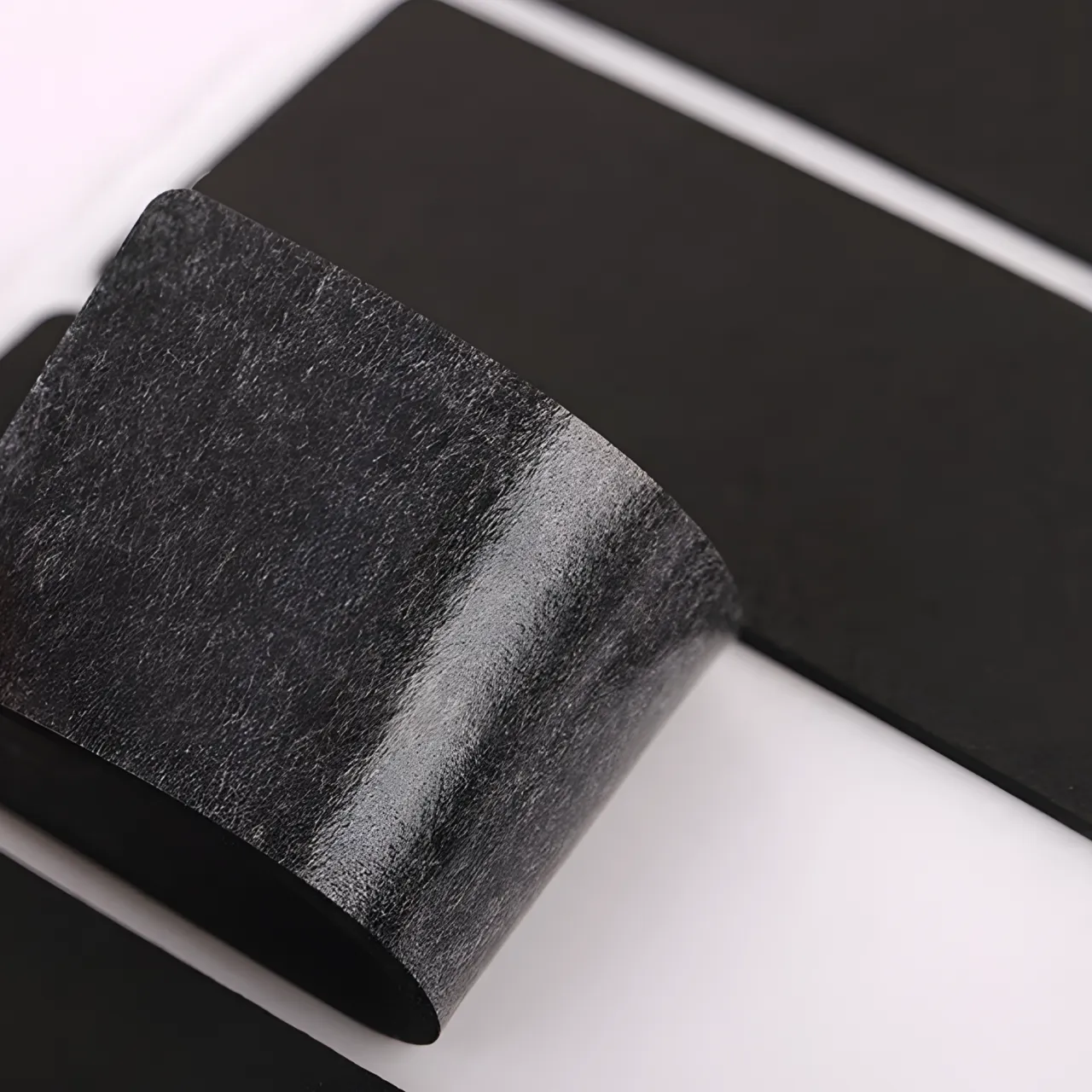

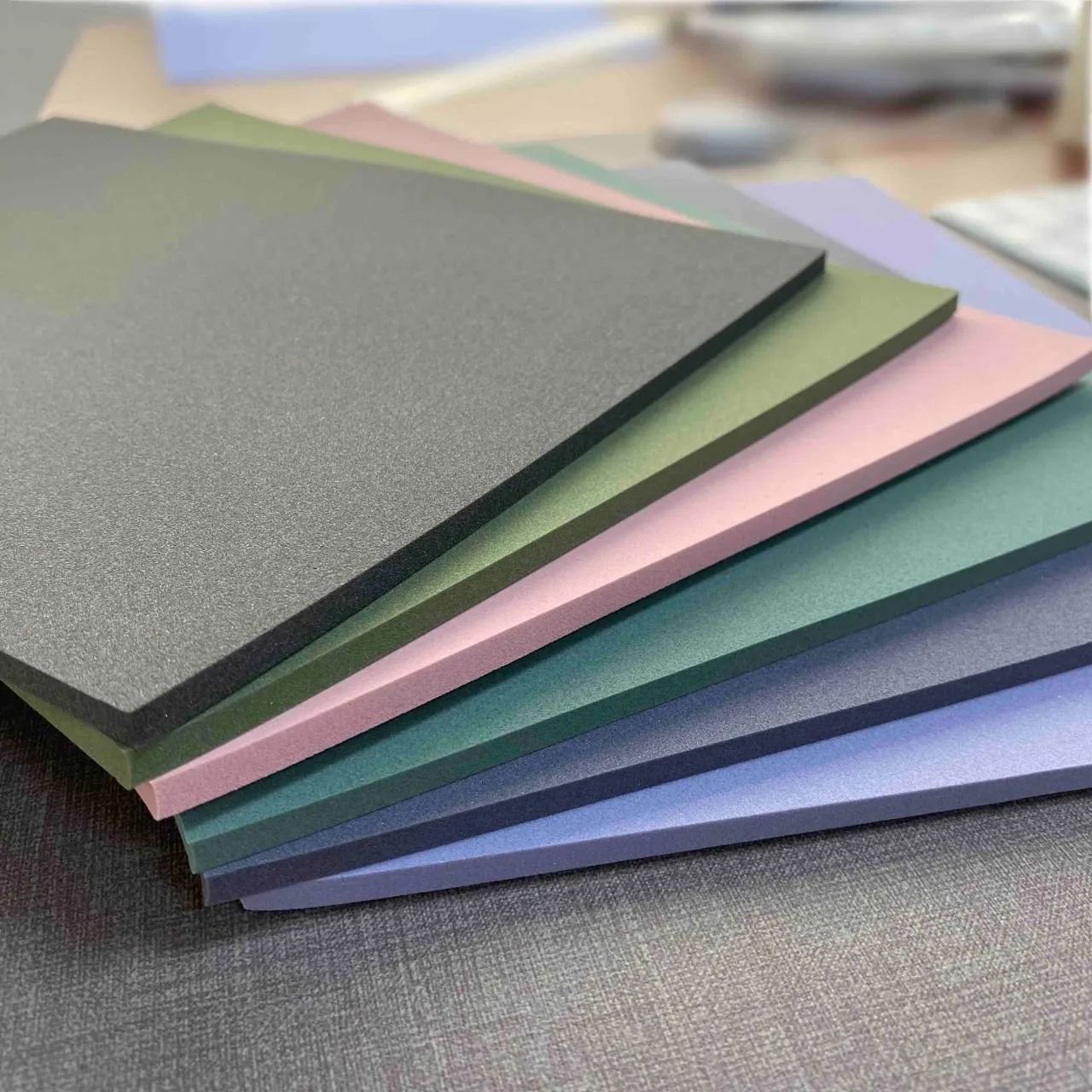

Colors & Textures

Standard black/white/gray; custom Pantone; smooth/embossed/cross‑hatch.

Functional Options

Flame‑retardant (UL 94), anti‑static/conductive, UV‑resistant, low VOC, PSA backing (3M/hot‑melt).

Documentation

Material datasheets and Certificates of Analysis on request.

EVA Foam Manufacturing Strengths (Why Work With Us)

Processes

Precision die‑cutting, CNC, thermoforming, lamination (foam/fabric/adhesive), slitting, grooving, embossing.

Engineering Support

DFM, material selection, tolerance analysis, stack‑ups, and cost optimization.

Capacity & Lead Times

Rapid prototyping and scalable production with flexible MOQs.

Tolerances

Typical thickness and outline tolerances aligned to process capability.

Supply Chain

Stable raw material sourcing, lot traceability, and forecast support.

Global Shipping

Export documentation and protective packaging standards ready.

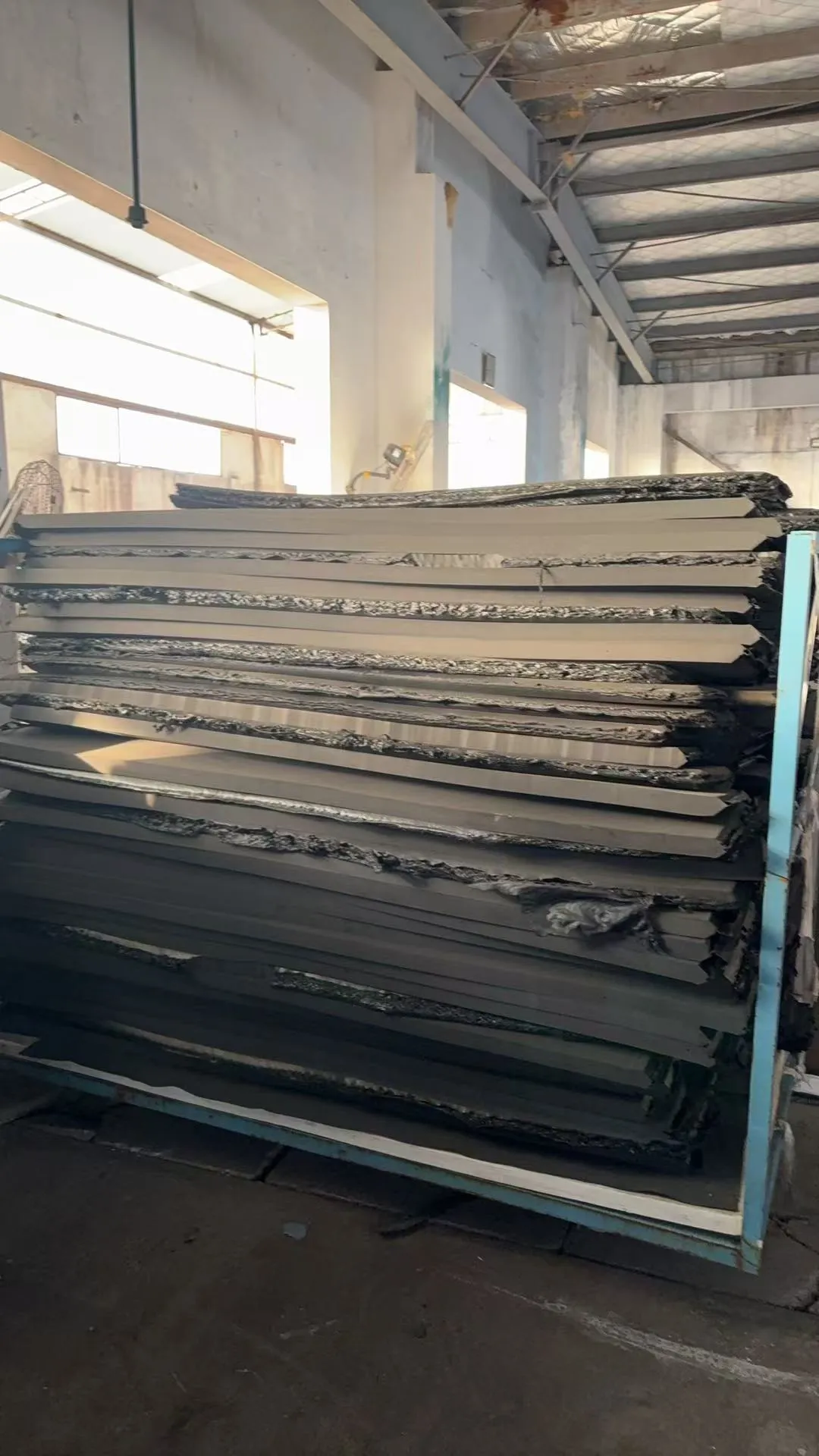

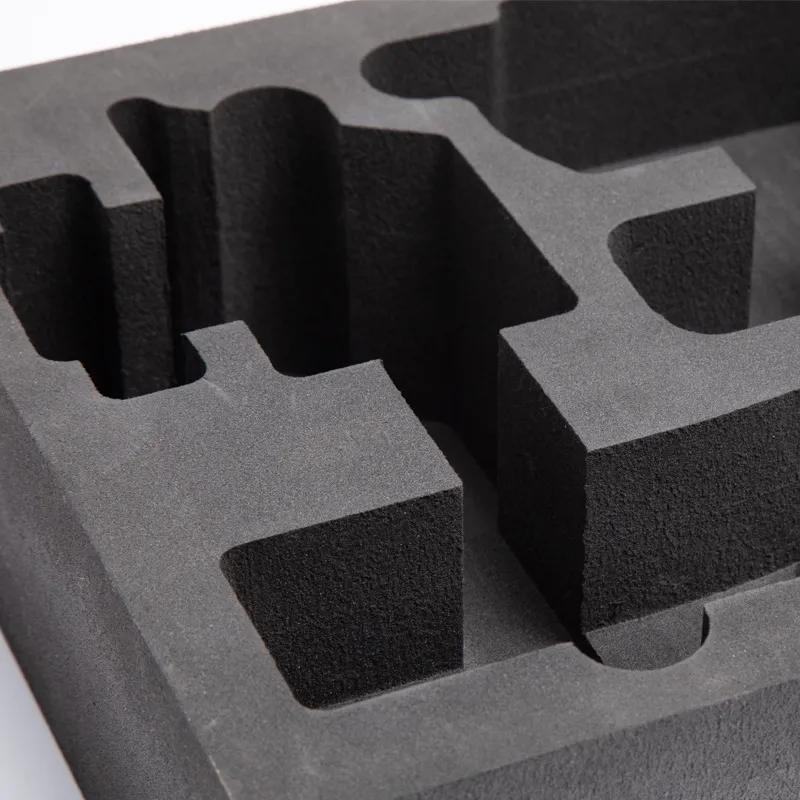

EVA Foam Project Gallery

Take a closer look at recent EVA foam builds—from complex molded interiors to roll stock and PSA-backed sheets—showcasing the range of finishes and fabrication results we deliver.

EVA Foam Quality Control & Compliance

Quality System

Incoming, in‑process, and outgoing inspections; documented control plans.

Compliance

RoHS/REACH statements; third‑party testing available upon request.

Traceability

Batch records with retained samples and lot‑level documentation.

EVA Foam Applications & Industry Use Cases

EVA foam supports demanding applications across packaging, sporting goods, flooring, automotive, consumer products, and creative builds. Examples include:

Creative & Cosplay

Lightweight armor, props, and models that hold detail, take coatings, and survive events and travel.

Consumer Goods & Toys

Safe, colorful EVA for craft kits, educational sets, and protective components in consumer products.

Fitness & Flooring

Interlocking tiles for gyms and play areas, and durable padding in sports equipment and protective packaging.

Specs & Selection Guide

Performance Targets

Choose density/hardness for the required impact absorption and feel.

Geometry

Match thickness to desired deflection and footprint.

Stack‑ups

Add functional layers (PSA, fabrics, films) to speed assembly and improve durability.

Environment

Consider temperature, humidity, UV exposure, and chemical resistance needs.

Get Recommendations

Share use case, loads, durability goals, and constraints for an engineering‑backed proposal.

EVA Foam in Production

Frequently Asked Questions (FAQ)

Can you build to my drawing and stack-up?

Yes. We review DFM and tolerances, recommend materials, and produce to your drawing, specification, and stack‑up requirements.

What are typical lead times for samples and production?

Rapid samples are available; production timing depends on volume, tooling, and materials. Share your target schedule and we will align a firm plan.

What is your MOQ?

Flexible MOQs based on part size, material grade, and process. Tell us your forecast or batch size for the best option.

Do you supply adhesive backing and laminations?

Yes. We offer multiple PSA brands and substrate laminations (fabrics/films) to streamline assembly and improve durability.

Can you provide compliance and test reports?

We provide RoHS/REACH statements and can arrange third‑party testing on request. Datasheets and Certificates of Analysis are available.

What is EVA foam made of?

EVA foam is made from Ethylene‑Vinyl Acetate, a copolymer of ethylene and vinyl acetate. The ratio of vinyl acetate content determines the softness, flexibility, and clarity of the foam. It is then expanded (foamed) to create a lightweight, closed‑cell structure with excellent cushioning and resilience.

What is the difference between EVA foam and PE foam?

EVA foam is generally softer, more flexible, and has a finer cell structure than standard PE (polyethylene) foam, making it better suited for wearables, cosplay, and applications requiring a smooth finish or precise die‑cutting. PE foam is typically stiffer and more economical for basic cushioning and void‑fill packaging. Both are closed‑cell and water‑resistant, but EVA offers a wider range of density, hardness, and color options.

Is EVA foam safe for children’s products and food-contact applications?

EVA foam is widely used in children’s flooring tiles, craft kits, and toys due to its low‑toxicity formulation and non‑sharp edges. For food‑contact or children’s product compliance, we can supply low‑VOC, non‑toxic grades and provide third‑party test reports (e.g., EN 71, ASTM F963, or specific food‑contact standards). Please specify your compliance requirements when requesting a quote.

Ready to Build Your EVA Foam Parts?

Send your drawings or requirements for a fast, engineering‑backed quote. We’ll recommend materials, stack‑ups, and processes to hit your targets on performance, cost, and timing.