EVA Foam Density Explained: Significato, Grafico e Come Scegliere

EVA foam density is one of the most important parameters affecting performance, durability, and long-term stability. However, density is often misunderstood or oversimplified as “hardness” or “foam stiffness,” which can lead to incorrect material selection.

This guide explains what EVA foam density actually means, how it is measured, and how engineers and product designers select the appropriate density for real-world applications.

1. What Does EVA Foam Density Mean?

EVA foam density refers to the mass of the material per unit volume, typically expressed in kg/m³. It reflects how much polymer material exists within the foam structure.

- Low density: More air content, lighter weight, higher compressibility

- High density: More polymer mass, greater load resistance, improved durability

Density is not a direct measure of surface hardness. Two EVA foams with identical Shore hardness can still behave very differently if their densities differ significantly.

2. Typical EVA Foam Density Chart

| Density Range (kg/m³) | Foam Characteristics | Common Applications |

|---|---|---|

| 33 – 60 | Ultra-light, highly compressible | Yoga mats, flotation inserts, soft packaging |

| 60 – 100 | Lightweight with basic structural support | Protective padding, entry-level footwear |

| 100 – 150 | Balanced cushioning and stability | Athletic midsoles, orthotics, sports gear |

| 150 – 220 | High strength, reduced compression set | Marine decking, tool trays, industrial pads |

| 220 – 280 | Very rigid, shape-retentive | Structural foam parts, heavy-duty components |

These ranges are representative of common EVA foam formulations. Actual performance depends on expansion ratio, cell structure, and additive systems.

3. How Density Affects EVA Foam Performance

Compression Resistance

Higher-density EVA foam resists deformation under sustained loads, making it suitable for applications where long-term thickness retention is critical.

Durability and Abrasion Resistance

As density increases, EVA foam generally exhibits improved abrasion resistance and lower compression set, extending service life in demanding environments.

Weight Considerations

Lower density significantly reduces part weight, which is essential for portable products and comfort-driven applications.

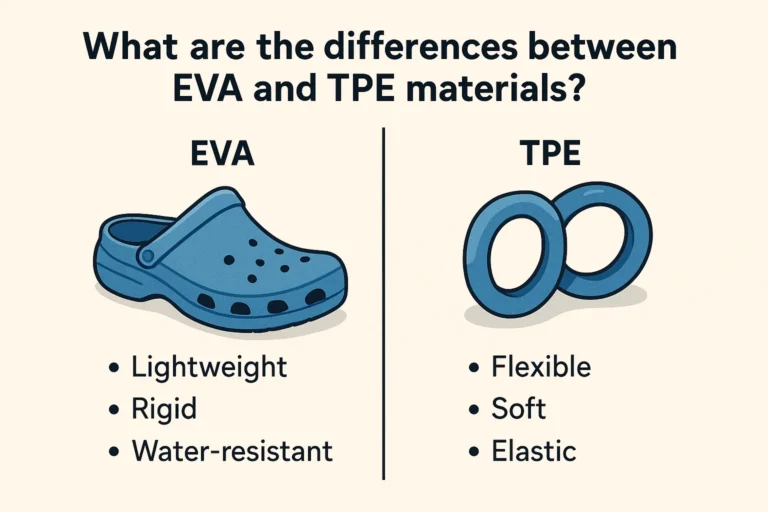

4. Density vs. Hardness: A Common Misconception

Density and hardness are related but independent variables. Hardness (Shore C or Shore A) measures surface indentation resistance, while density reflects the internal mass distribution of the foam.

For a detailed explanation of Shore hardness scales and their practical differences, see our related guide: EVA Foam Density & Hardness: Shore A vs Shore C

5. How to Choose the Right EVA Foam Density

Engineers typically select density based on functional priorities:

- Maximum cushioning and weight reduction: 33–80 kg/m³

- Balanced comfort and durability: 80–150 kg/m³

- Structural stability and wear resistance: 150–220 kg/m³

- Minimal deformation under load: 220+ kg/m³

Density selection should always be validated with physical samples, especially for load-bearing or outdoor applications.

6. Frequently Asked Questions About EVA Foam Density

Q: Does higher density always mean better quality?

No. Higher density improves strength and durability, but may reduce cushioning and increase weight. The optimal density depends entirely on application requirements.Q: Can EVA foam density be customized?

Yes. Density can be adjusted by controlling formulation and expansion ratio within practical manufacturing limits.Q: Is density related to water absorption?

Indirectly. Higher-density EVA foam typically has a tighter cell structure, which can reduce water absorption in wet environments.

Need Help Selecting EVA Foam Density?

Our team provides density samples, technical data sheets, and application-specific recommendations for EVA foam projects.Request Technical Support