使用済みプラスチックグローブマシンとは何ですか?

In sectors where hygiene and safety are paramount, such as healthcare, food service, and cleanroom environments, disposable gloves are an indispensable part of daily operations. But have you ever paused to consider the technology behind the production of these essential items? The unsung hero of this process is the 一次性プラスチックグローブ製造機, a sophisticated piece of equipment engineered for precision, speed, and reliability. For buyers and industry professionals, understanding the mechanics and capabilities of these machines is crucial for making informed investment decisions that can significantly impact operational efficiency and product quality.

From raw material to finished product, the journey of a disposable glove is a marvel of modern automation. This comprehensive guide will delve into the world of disposable glove manufacturing, exploring the intricate processes, the different types of machines available, and the key features that define a high-quality production line. We will also highlight how industry leaders like ダマオ・テック are pushing the boundaries of innovation to deliver machinery that meets the evolving demands of the global market.

The Evolution of Glove Manufacturing: From Manual Labour to High-Speed Automation

The production of disposable gloves has transformed dramatically over the decades. Early methods were labour-intensive and slow, often resulting in inconsistent quality. The advent of automation revolutionised the industry, paving the way for machines that could produce thousands of gloves per hour with minimal human intervention. This shift not only boosted production volumes but also enhanced hygiene standards by reducing manual contact during the manufacturing process.

Today’s state-of-the-art disposable plastic glove machines, like those engineered by ダマオ・テック, represent the pinnacle of this evolution. Integrating advanced robotics, intelligent control systems, and precision engineering, these machines offer unparalleled efficiency, consistency, and versatility, making them a cornerstone of modern personal protective equipment (PPE) production.

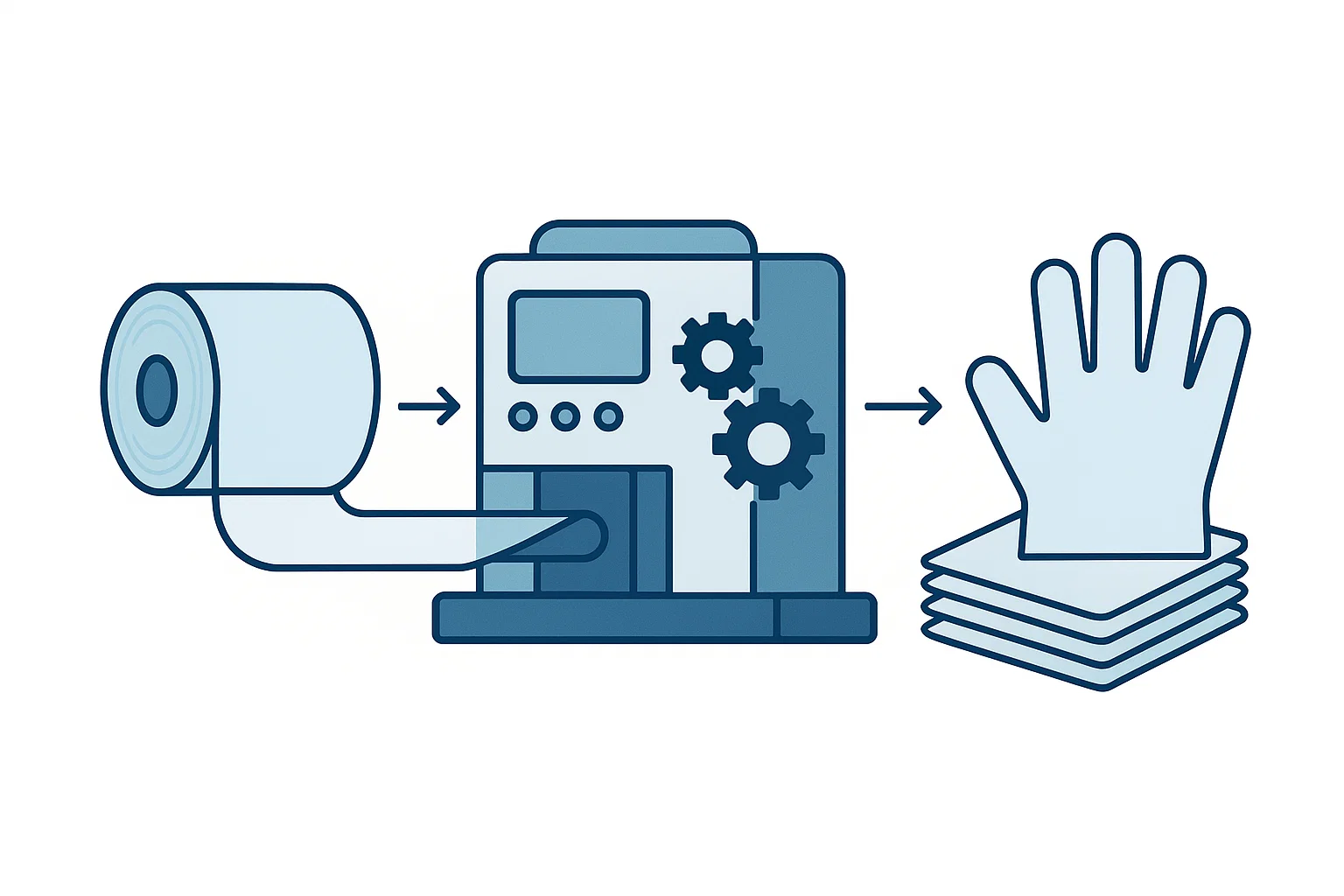

How Does a Disposable Plastic Gloves Machine Work? A Step-by-Step Breakdown

While different machines exist for various materials like PE and TPE, the fundamental process of converting plastic film into a finished glove involves several key stages. A modern, fully automatic line automates each step for a seamless workflow.

1. Material Feeding and Unwinding

The process begins with a large roll of plastic film—typically polyethylene (PE) or thermoplastic elastomer (TPE)—loaded onto the machine. An automated unwinding system, often controlled by a frequency converter, feeds the film with high precision to ensure a smooth and consistent supply into the production line.

2. Film Forming and Heating

For certain types of gloves, particularly those made from materials like CPE (chlorinated polyethylene) or TPE, the machine first forms two layers of film in parallel. These layers are then heated to the optimal temperature, preparing them for the crucial moulding stage. This heating process ensures the material is pliable enough to be sealed and cut accurately.

3. Glove Moulding, Sealing, and Cutting

This is the core of the manufacturing process where the glove takes shape. The heated plastic film passes through a station equipped with a hand-shaped mould. The machine uses a heat-sealing and cutting mechanism to press the layers of film together, simultaneously welding the edges and cutting out the glove’s outline. The quality and precision of this mould are paramount to producing a glove that is not only perfectly shaped but also has strong, reliable seams. Companies like ダマオ・テック invest heavily in the engineering of these moulds to guarantee consistency and durability.

4. Automatic Waste Stripping

Once the glove shape is cut, the surrounding excess film, known as waste material, must be removed. In older, semi-automatic systems, this required manual labour. However, a fully automatic disposable gloves machine integrates an automated waste stripping unit. This system mechanically separates the waste from the finished gloves, which can then be collected for recycling, improving sustainability and reducing manual effort.

5. Counting and Stacking

In the final stage, the finished gloves are automatically counted and stacked. Advanced systems use sensors to ensure accurate counts before stacking the gloves neatly, ready for packaging. This automation minimises handling, maintains hygiene, and prepares the product for distribution efficiently.

Types of Disposable Plastic Gloves and Their Specialised Machines

The term “plastic gloves” covers a range of materials, each suited to different applications and requiring specific machine configurations.

- PE (Polyethylene) Glove Machines: PE gloves, made from either High-Density (HDPE) or Low-Density (LDPE) polyethylene, are the most common and cost-effective type of disposable plastic glove. They are widely used in the food service industry for tasks that require frequent glove changes. PE glove machines are designed for high-speed production of these lightweight gloves.

- TPE (Thermoplastic Elastomer) Glove Machines: TPE gloves offer a significant upgrade from standard PE gloves. They provide a softer, more flexible fit with better elasticity, often compared to vinyl gloves. TPE machines, such as those developed by ダマオ・テック, are engineered to handle the unique properties of this material, ensuring a high-quality finish and comfortable user experience.

- CPE (Chlorinated Polyethylene) Glove Machines: CPE gloves are known for their durability and soft feel. The production machines for CPE gloves are similar to TPE machines, involving a film-casting or blowing process followed by heat sealing and cutting.

Key Features to Consider When Investing in a Disposable Plastic Gloves Machine

For buyers and production managers, selecting the right machine is a critical decision that impacts productivity, cost, and market competitiveness. Here are the essential features to evaluate:

- Production Speed and Capacity: Look for a machine that can meet your volume demands. High-speed models can produce anywhere from 40 to over 140 pieces per minute per line, with many machines featuring a dual-line setup to double the output.

- Level of Automation: A 完全自動式一次性手套製造機 significantly reduces labour costs and the potential for human error. Features like automatic waste removal, counting, and stacking are essential for a truly efficient and hygienic production line.

- Material Compatibility and Versatility: A machine that can handle various materials like PE, CPE, and TPE provides greater flexibility to meet diverse market needs and adapt to changing customer demands. The ability to customise glove shapes and sizes is also a significant advantage.

- Build Quality and Component Reliability: The machine’s longevity and performance depend on its construction and the quality of its components. Look for machines built with a robust steel frame for stability and equipped with reliable electronics from reputable brands. ダマオ・テック, for instance, utilises a microcomputer touchscreen and high-quality components to ensure dependable, low-noise operation.

- Energy Efficiency and Operating Costs: In today’s competitive market, minimising operational expenses is key. An energy-efficient design not only lowers electricity bills but also contributes to a more sustainable manufacturing process, offering a faster return on investment.

- After-Sales Service and Technical Support: A reliable manufacturer provides comprehensive support, including installation, training, and readily available spare parts. This partnership is crucial for ensuring minimal downtime and maintaining peak production efficiency.

Why Damao Tec Sets the Standard in Disposable Glove Machine Technology

In the specialised field of protective equipment manufacturing, ダマオ・テック has established itself as a trusted leader through a relentless commitment to quality, innovation, and customer-centricity. Our deep-seated Experience in the industry is reflected in the robust design and superior performance of our machines. We demonstrate our Expertise by integrating cutting-edge automation and intelligent control systems that empower our clients to achieve unparalleled production efficiency.

当社の Authoritativeness is built on a foundation of proven success, with ダマオ・テック machines operating in facilities worldwide, consistently delivering high-quality products. Most importantly, we earn our clients’ Trustworthiness through transparent processes, reliable after-sales support, and machinery that is built to last. By choosing ダマオ・テック, you are not just buying a machine; you are investing in a partnership dedicated to your success.

The Future of Glove Production: Sustainability and Smart Technology

The future of disposable glove manufacturing is being shaped by two major trends: sustainability and smart technology. Manufacturers are increasingly looking for machines that minimise waste and can process biodegradable or recyclable materials. Simultaneously, the integration of IoT (Internet of Things) and AI-driven analytics will enable “smart” production lines that can self-diagnose issues, optimise performance in real-time, and provide valuable data for production planning. ダマオ・テック is actively engaged in research and development to incorporate these future-forward features into our next generation of disposable plastic glove machines.

結論

The 一次性プラスチックグローブ製造機 は、PPE、食品サービス、医療用品産業のいずれの製造業者にとっても不可欠な資産です。単なる機器ではなく、生産のエンジンであり、生産量、品質、利益率に直接的な影響を与えます。複雑な製造プロセス、異なる機械の種類、検討すべき主要な機能を理解することで、購入者や業界専門家は長期的な利益をもたらす戦略的な投資を行うことができます。

自动化と技術が進化し続ける中で、経験豊富で革新的な製造業者である ダマオ・テック とパートナーシップを結ぶことで、競争の激しい環境で繁栄するために必要なツールとサポートを確保し、世界中の人々とプロセスを守る重要な製品を提供することができます。

常に質問(FAQ)

1. 半自動と全自動の disposable plastic gloves machine の主な違いは何ですか?

半自動機は、通常、手袋がカットされた後の廃棄フィルムの取り外しなどの特定のプロセスステップに対して手動介入が必要です。一方、全自動機は、材料供給、密封、カット、廃棄物の取り除き、カウントを含むすべてのステップに自動化システムを統合しており、労働コストを大幅に削減し、効率を向上させます。

2. 多様な disposable plastic gloves machine が取り扱える原材料は何ですか?

高品質で多様な機械は、様々な熱可塑性フィルムと互換性があります。最も一般的な材料はHDPE(高密度ポリエチレン)とLDPE(低密度ポリエチレン)です。Damaoなどの多くの高度なモデルは、CPE(塩素化ポリエチレン)とTPE(熱可塑性エラストマー)フィルムを効率的に処理することもできます。これにより、製造業者は様々な市場の需要に応じた異なるタイプの手袋を生産することができます。 ダマオ・テック,

3. Disposable plastic gloves machine はどの程度のメンテナンスが必要ですか?

現代の機械は耐久性とメンテナンスの容易さに設計されています。定期的なメンテナンスは、密封およびカット金型の清掃、供給システムの緊張の確認、電気機器および制御システムが正しく機能しているかの確認を含みます。高品質の部品と便利な潤滑システムを持つ機械は、このプロセスを簡素化し、長い運転寿命と一貫したパフォーマンスを確保します。

4. 手袋のサイズと形状は機械でカスタマイズできますか?

はい、現代の disposable glove machines の主要な特徴の1つは製品のカスタマイズ能力です。手袋の形状とサイズは、密封およびカットステーションで使用される金型によって決定されます。これらの金型は通常交換可能であり、製造業者は小さい、中の、大きなサイズなど、様々なサイズ(例:小さい、中、大きい)や特定のアプリケーションやクライアントの要望に応じたカスタム形状を生産することができます。