EVAフォームの欠点とは何ですか?客観的な分析

エチレン・ビニルアセテート(EVA) 軽量で柔軟な緩衝材として広く使用されていますが、, Damao Tech believes that informed decisions require a full understanding of a material’s limitations. Recognizing the disadvantages of EVAフォーム is crucial for engineers and buyers to ensure product longevity and safety.

EVAフォームの核心的な欠点

EVAフォームは多くの分野で優れていますが、環境や機械的な要因によって性能に影響を与えることがあります。以下に主な欠点を説明します。

低熱抵抗性

EVAフォームは、他のエラストマーに比べて比較的低い融点を持っています。高温環境(70°C/158°Fを超える)では、変形、縮み、構造の維持性の喪失が起こる可能性があります。.

永続的な圧縮

時間が経つと、繰り返しの重い負荷の下で、EVAフォームは「圧縮セット」となることがあります。これは、元の厚みに完全に戻らない可能性があり、最終的には緩衝性能を失うことを意味します。.

化学物質に対する感受性

時間が経つと、繰り返しの重い負荷の下で、EVAフォームは「圧縮セット」という問題を引き起こすことがあります。これは、元の厚みに完全に戻らない可能性があり、緩衝性を失うことになります。.

リサイクルの課題

熱可塑性エラストマー(TPE)とは異なり、標準的なEVAフォームは交絡材であり、従来の施設で溶かしてリサイクルするのが難しいです。.

How Damao Tech Mitigates These Drawbacks

Understanding these challenges is the first step toward solving them. At Damao Tech, これらの課題を理解することは、解決に向けての第一歩です。当社では、.

| 欠点 | 欠点 | 業界への影響 |

|---|---|---|

| Compression Set | Soles flatten over time | High-resiliency blends that increase energy return. |

| Surface Wear | Easily scratched | Custom skin-forming technology for a tougher exterior. |

| Odor (Off-gassing) | Unpleasant “new foam” smell | Vacuum-deodorizing processes to minimize VOCs. |

| Eco-Impact | Landfill waste | Integration of 20%+ GRS-certified recycled content. |

Damao Techの解決策

At Damao Tech, we want your project to succeed. You might consider alternatives to EVA foam if:

- 高温曝露: 自動車エンジンや高温の工業地域で使用される製品(シリコンやEPDMを検討してください)。.

- 恒常的な重い負荷: 重機の振動緩衝用(高密度PUやゴムを検討してください)。.

- 完全な循環: あなたのブランドが100%の閉ループリサイクル性を必要とする場合(当社のTPE代替品を検討してください)。.

EVAが適しているかどうか分からない場合は? 当社の技術チームが、特定のストレステスト要件に基づいた素材比較を行います。.

素材技術者と相談する常に質問されること

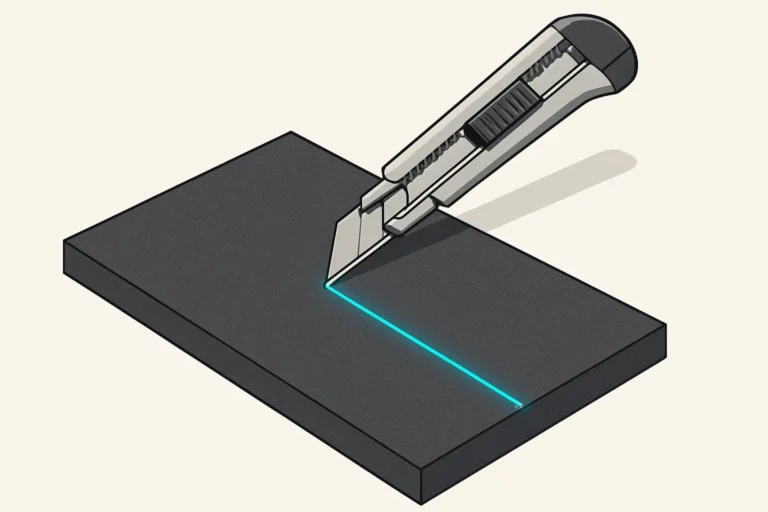

なぜ、表面が切られると水が通らないか? Damao Tech 閉孔EVAフォームを使用しているため、表面が切られると材料も水に通らない。しかし、深い突き刺しが切られた細胞の間に水分を捕らえることができる。.

高品質のEVAフォームは無毒である。しかし、低品質のフォームにはホルメアミドが含まれている可能性がある。Damao Techはすべての製品がSGS検査を受け、有害化学物質から自由であることを保証します。.

直接のUV線と熱は、閉孔内の空気を拡張し収縮させる。その結果、時間が経つにつれて「熱収縮」が発生します。この効果に対処するために、UV安定化版を提供しています。.

すべてのフォームは最終的に老朽化するが、Damao Techの高密度グレードを選ぶことで、標準の工芸品グレードのフォームに比べて製品の寿命を大幅に延ばすことができます。.

今日正しい材料仕様を取得してください

材料の「欠点」は、しばしば不適切な仕様の選択の問題です。. Damao Tech 密度、硬度、添加物を特定の環境に合わせて一致させるのに役立ちます。.

サンプルと見積もりを依頼してください