EVA vs. Espuma de PE: Guia Completo para Escolher a Espuma Correta

Estancado tentando decidir entre espuma de EVA e espuma de PE para seu próximo projeto? Você não está sozinho. À primeira vista, podem parecer semelhantes, mas essas duas espumas populares têm características distinto que as tornam mais adequadas para diferentes aplicações. Escolher a certa é crucial para o desempenho, durabilidade e custo-effectiveness.

Então, como você sabe qual escolher?

Não se preocupe, estamos aqui para ajudar. Como especialistas em soluções de espuma, aqui na Damao Tech estamos aqui para esclarecer suas dúvidas. Este guia completo o levará a tudo que você precisa saber sobre espuma de EVA e PE, ajudando você a tomar uma decisão informada com confiança.

O que é Espuma de EVA? O Versátil

A espuma de EVA (Etileno-Vinil Acetato) é uma espuma de célula fechada macia, mas durável, conhecida por sua versatilidade e flexibilidade semelhante ao borracha. O conteúdo de acetato de vinila lhe confere uma suavidade e elasticidade que muitas outras espumas não têm. É o material que você encontrará em tudo, desde tapetes de ioga e fantasias de cosplay até embalagens premium e dispositivos médicos.

Características Principais da Espuma de EVA:

- Suave e Flexível: Possui uma sensação macia e elástica que oferece excelente amortecimento e conforto.

- Alta Durabilidade: Resistente a rasgos e compressão, retornando à sua forma original após uso repetido.

- Absorção Superior de Choque: Suas propriedades elásticas a tornam excelente para absorver impactos.

- Resistência a UV e ao Tempo: Mantém-se bem contra os elementos, tornando-se adequada para aplicações ao ar livre.

- Brilho: frequentemente tem uma aparência lisa e brilhante que dá um aspecto profissional aos projetos.

Para uma análise mais profunda de suas propriedades e aplicações, consulte nosso guia completo sobre Foam EVA.

O que é Espuma de PE? O Trabalhador Resiliente

A espuma de PE (Polietileno) é outra espuma de célula fechada amplamente utilizada. Geralmente é mais rígida e firme do que a EVA e é conhecida por seu excelente relação entre resistência e peso. Pense na espuma resistente usada para embalar eletrônicos delicados, isolar tubulações ou fornecer flutuabilidade em equipamentos marítimos — muitas vezes é espuma de PE.

Características Principais da Espuma de PE:

- Firme e Rígida: Fornece suporte estrutural e é muito mais rígida do que a EVA.

- Leve: Apesar de sua resistência, a espuma de PE é incrivelmente leve.

- Excelente Resistência a Químicos: Resistente a solventes e outros químicos.

- Excelente Isolamento Térmico: Sua estrutura a torna altamente eficaz como isolante.

- Custo-Effectiveness: A espuma de PE é frequentemente uma opção mais econômica para aplicações em grande volume.

Comparação entre Espuma de EVA e Espuma de PE: Uma Análise Padrão

Vamos colocá-las lado a lado para ver como se saem em áreas de desempenho chave.

| Recurso | Foam EVA | Espuma de PE | O Vencedor é… |

| Durabilidade e Resiliência | Excelente. Retorna bem, alta resistência a rasgos. | Boa. Forte, mas pode ser propensa a rachaduras sob estresse alto. | Foam EVA para uso a longo prazo e repetido. |

| Suavidade e Amortecimento | Excelente. Sensação suave e semelhante à borracha. | Boa a razoável. Mais firme e rígida. | Foam EVA para conforto e amortecimento. |

| Absorção de Choque | Excelente. Absorve energia de impacto eficazmente. | Muito boa. Ideal para estabilização e proteção de itens. | Foam EVA para proteção dinâmica de impacto. |

| Custo | Moderado | Menor. Geralmente mais acessível. | Espuma de PE para projetos com foco no orçamento. |

| Peso | Leveza | Extremamente leve. | Espuma de PE quando cada grama conta. |

| Isolamento Térmico | Boa | Excelente. | Espuma de PE para aplicações de controle de temperatura. |

| Aparência e Brilho | Liso, brilhante e frequentemente mais vibrante na cor. | Mais texturizado, acabamento mate. | Foam EVA Para apelo estético. |

H3: Qual é o Melhor para a Sua Aplicação?

A melhor escolha realmente depende das suas necessidades específicas.

- Escolha a Espuma EVA se precisar de:

- Conforto e Amortecimento: Perfeito para tapetes de chão, almofadas esportivas, calçados e braços ortopédicos.

- Aesthetics de Alta Qualidade: Ideal para armaduras de cosplay, criação de propriedades e caixas de produtos de consumo onde a aparência importa.

- Durabilidade a Longo Prazo: Excelente para produtos que serão esticados ou comprimidos repetidamente, como inserções personalizadas para ferramentas frequentemente usadas.

- Escolha a Espuma PE se precisar de:

- Embalagem Econômica: A escolha ideal para inserções de envio para proteger itens frágeis sem comprometer o orçamento.

- Suporte Estrutural: Excelente para aplicações onde a rigidez é necessária, como enchimentos de construção ou juntas industriais.

- Isolação ou Flutuabilidade: O vencedor claro para isolamento térmico, isolamento de tubulação e dispositivos de flutuação marítima.

Damao Tech: Seu Parceiro em Soluções de Espuma

independentemente do seu projeto exigir a durabilidade flexível Foam EVA ou a rigidez leve da espuma PE, temos a expertise para entregar. Na Damao Tech, oferecemos espuma de alta qualidade em várias formatos para atender às suas especificações exatas:

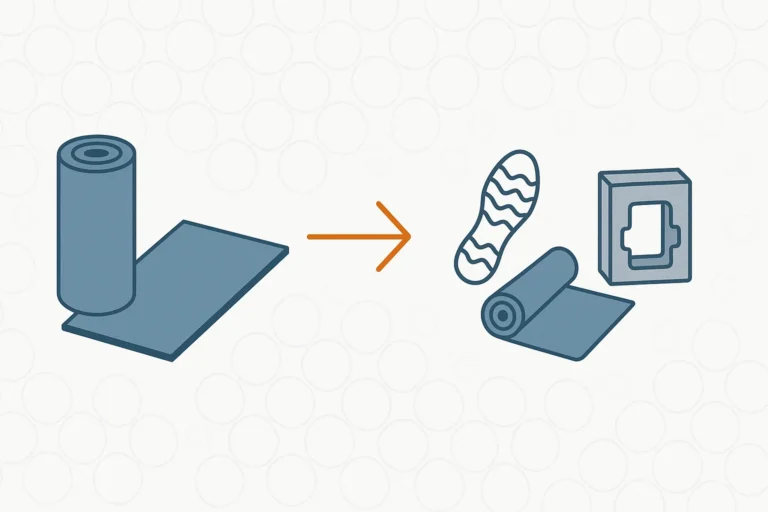

- Folhas e Rolos de Espuma: Para produção em grande escala ou corte personalizado.

- Produtos Fabricados sob Medida: Soluções cortadas a laser, roteirizadas CNC e laminadas projetadas para a sua aplicação única.

- Soluções Específicas para Aplicações: De peças automotivas a equipamentos de proteção, desenvolvemos produtos de espuma que funcionam.

Perguntas Frequentes (FAQ)

1. A espuma EVA é à prova d'água?

Sim, porque a espuma EVA é uma espuma “de célula fechada”, suas células não estão interconectadas, tornando-a altamente resistente à água. Por isso, é frequentemente usada em aplicações marinhas, brinquedos de piscina e equipamentos ao ar livre.

2. Você pode colar espuma EVA e PE?

Absolutamente. Para ambas as espumas EVA e PE, o cola de contato é o adesivo mais popular e eficaz. Um pistola de cola quente de alta temperatura também funciona bem, especialmente para montagem rápida. Sempre trabalhe em um ambiente bem ventilado ao usar cola de contato.

3. Qual espuma é mais ecológica?

Ambas as espumas EVA e PE são tipos de plástico (polímeros), e seu impacto ambiental depende da manufatura e do descarte. No entanto, ambas são geralmente consideradas mais benignas do que opções como PVC. Muitas espumas PE e EVA são recicláveis, embora os serviços possam ser limitados. Na Damao Tech, estamos comprometidos em explorar práticas sustentáveis em nossa produção de espuma.

4. A espuma EVA é segura para crianças?

Sim, a espuma EVA é amplamente considerada segura e é amplamente usada em brinquedos infantis, tapetes de brincadeira e materiais de artesanato. É não tóxica e não contém ftalatos, tornando-se uma escolha popular para produtos destinados a crianças.

Pronto para Iniciar Seu Projeto?

Escolher a espuma certa não precisa ser complicado. Agora que você entende as principais diferenças entre a espuma EVA e PE, você está pronto para o próximo passo.

nossa equipe de especialistas em espuma na Damao Tech está aqui para ajudar você a escolher o material e o formato perfeito para suas necessidades. Se você tiver um design detalhado ou apenas uma ideia bruta, fornecemos a orientação e os produtos de qualidade para trazer sua visão à vida.

Entre em contato conosco hoje para uma consulta gratuita ou para solicitar um orçamento! Vamos construir algo excelente juntos.