EVA Foam Density & Hardness Guide: Shore A vs Shore C Explained

Selecting the correct EVA foam is not simply a matter of softness or thickness. In industrial manufacturing, footwear development, marine applications, and protective packaging, الكثافة و Shore hardness directly affect durability, energy return, machinability, and service life.

At Damao Tech, we manufacture EVA foam sheets and rolls with tightly controlled density and hardness ranges to support precise engineering requirements.

Density and Shore hardness are correlated but fundamentally different parameters. Density primarily affects weight, compression resistance, and structural stability, while Shore hardness measures surface resistance to indentation under a standardized load.

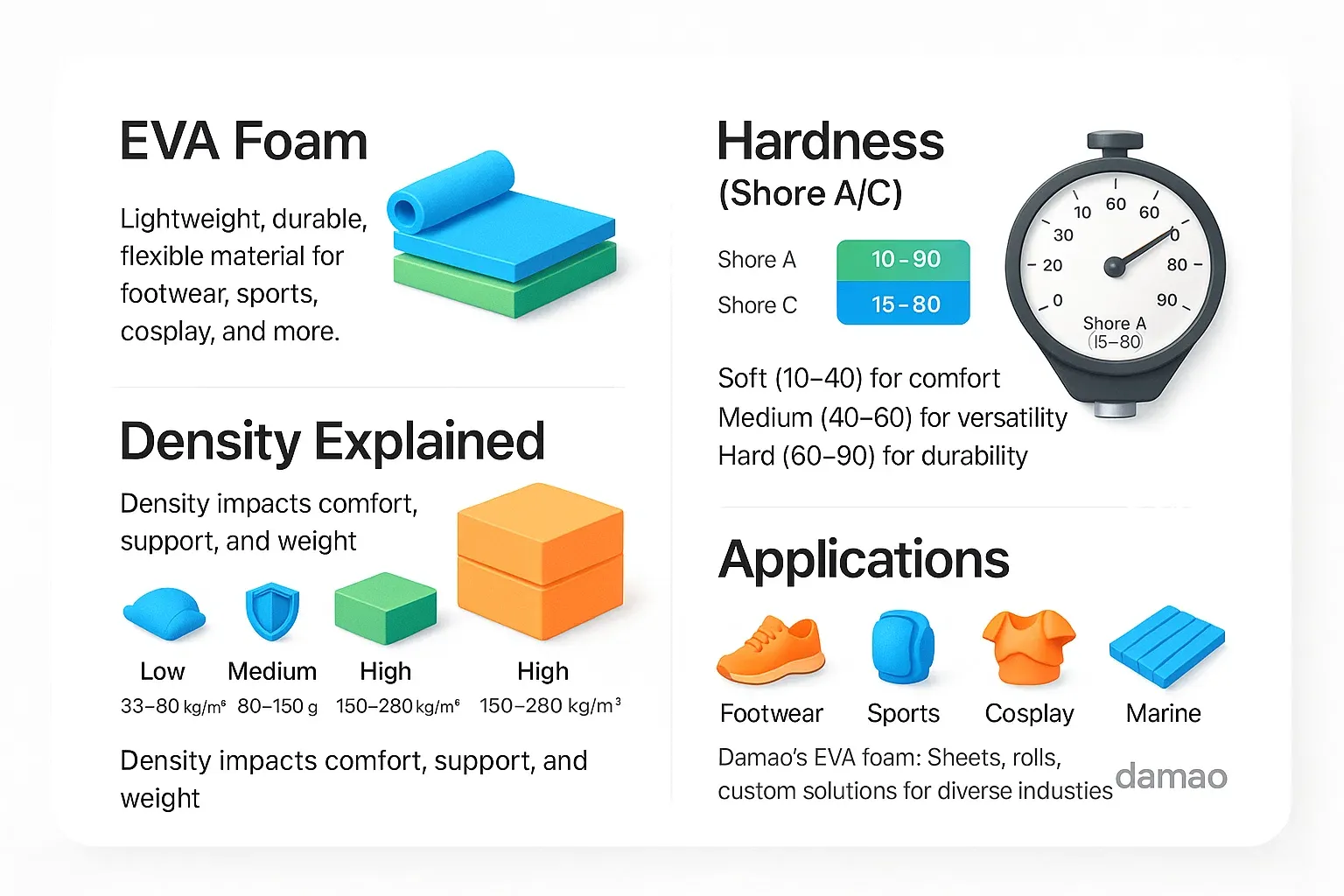

1. EVA Foam Density Classification (kg/m³)

Density determines how much material mass exists per unit volume. Higher-density EVA generally provides better load-bearing capacity, dimensional stability, and abrasion resistance, while lower-density foam prioritizes cushioning and weight reduction.

Low Density (33–80 kg/m³)

Used for yoga mats, soft protective packaging, flotation inserts, and comfort-focused cushioning where low weight and compressibility are critical.

Medium Density (80–150 kg/m³)

The most common range for athletic footwear midsoles, orthotic components, sports equipment padding, and general-purpose industrial foam parts.

High Density (150–280 kg/m³)

Preferred for marine decking, industrial gaskets, tool control foam, and applications requiring higher stiffness, wear resistance, and shape retention.

2. EVA Foam Hardness Testing Standards (Shore A & Shore C)

EVA foam hardness is commonly measured using ASTM D2240. Due to EVA’s cellular structure, different Shore scales are used depending on formulation and industry.

- Shore C: Common in footwear, sports, and foam-specific industries

- Shore A: Used when comparing EVA to rubber or elastomer components

Because Shore A and Shore C use different indenters and spring forces, there is no exact mathematical conversion between the two scales. The table below reflects commonly observed industry reference ranges.

| Shore C (EVA Foam) | Approx. Shore A | Typical Application |

|---|---|---|

| 15 – 25 درجة مئوية | 5 – 10 واط | مرآب ناعم للغاية، أظافر علاجية |

| 35 – 45 درجة مئوية | 20 – 25 واط | أظافر رياضية معتدلة، مرآب ماصة للصدمات |

| 55 – 65 درجة مئوية | 35 – 45 واط | مرآب marin، مرآب تحكم الأدوات، لوحات حماية |

| 75 – 85 درجة مئوية | 55 – 70 واط | أجزاء الصناعية القاسية، مكونات مرآب هندسية |

قيم Shore A وShore C المذكورة أعلاه هي نطاقات مرجعية تقريبية بناءً على صيغ مرآب EVA الشائعة. قد تختلف النتائج الفعلية من اختبار إلى آخر اعتمادًا على الكثافة، نسبة التوسع، بنية الخلية، وظروف الاختبار. تحقق دائمًا من مواصفات المواد باستخدام عينات مادية.

3. كيفية اختيار مهندسي مرآب EVA: منطق عملي

بدلاً من اختيار الكثافة أو القسوة بشكل منفرد، mهندسون عادةً يعملون بالعكس من الطلب من المتطلبات الوظيفية:

- هل تركزون على المرآب أو امتصاص الطاقة؟

→ ابدأوا بالنطاق المحدد من Shore C، ثم قموا بتعديل الكثافة للحفاظ على المرونة. - هل أنتم مهتمون بالاستقرار الحجمي أو التشغيل؟

→ ابدأوا بالنطاق المحدد من الكثافة، ثم قموا بتعديل القسوة بتفصيل. - هل تحتاجون إلى تشكيل الحرارة أو التشكيل الحراري؟

→ كثافة متوسطة إلى عالية مع Shore C متوسطة إلى مرتفعة يتحسن بذلك تعريف الحافة. - هل تعملون في الهواء الطلق أو البحر؟

→ كثافة أعلى ونطاق Shore C متوسط إلى مرتفع لتحسين مقاومة التآكل والتشبث.

4. مرجع التخصيص بناءً على التطبيق

- الأحذية: كثافة منخفضة إلى متوسطة، 20-35 Shore C للراحة والانعكاس

- البحرية: كثافة عالية، 60-65 Shore C للمقاومة ضد الأشعة فوق البنفسجية والتصاق المضاد

- Cosplay & Props: كثافة متوسطة إلى مرتفعة، 45-70 Shore C للشكيل الحراري والمتانة

- حماية التعبئة والتغليف: كثافة منخفضة، 35-45 Shore C للامتصاص المفاجئ

5. الأسئلة الشائعة

نعم. من خلال تعديل التركيبة وتحديد نسبة التوسع، يمكن تحقيق مستويات صلابة Shore محددة داخل نطاقات كثافة مختلفة، داخل الحدود العملية.

سؤال: هل تقدم بيانات تقنية و عينات؟نعم. نقدم بيانات المواد و العينات الفيزيائية للتحقق، وهو ما يُنصح به بشدة للعناصر الحرجة.

هل تحتاج إلى دعم إضافي للمواد البوليمرية على مستوى الهندسة؟

اطلب بيانات التقنية، عينات صلابة Shore، أو توصيات محددة للتطبيق من فريق موادنا.

تواصل معنا للحصول على الدعم التقني