Die ultimative Anleitung zur Herstellung von EVA-Schaummaterial

Ethylenterephthalat-Vinylacetat, besser bekannt als EVA-Dämmstoff, ist eines der vielseitigsten und am häufigsten verwendeten Materialien in der modernen Industrie. Von der Schutzverpackung für sensible Elektronik bis hin zu den bequemen Sohlen Ihrer Lieblingslaufschuhe machen ihre einzigartigen Eigenschaften es zu einer unverzichtbaren Ressource. Aber haben Sie sich jemals gefragt, wie dieses bemerkenswerte Material hergestellt wird?

Bei Damao Tech sind wir spezialisiert auf den gesamten Lebenszyklus dieses Materials, von den Rohkomponenten bis zu präzise fertiggestellten Produkten. Dieser Leitfaden führt Sie durch den komplexen Prozess der EVA-Dämmstoffherstellung und zeigt die Expertise und Technologie auf, die erforderlich sind, um ein Produkt zu schaffen, das den höchsten Standards an Qualität und Leistung entspricht. EVA-Dämmstoff-Herstellung, showcasing the expertise and technology required to create a product that meets the highest standards of quality and performance.

What Exactly is EVA Foam? The Science Behind the Versatility

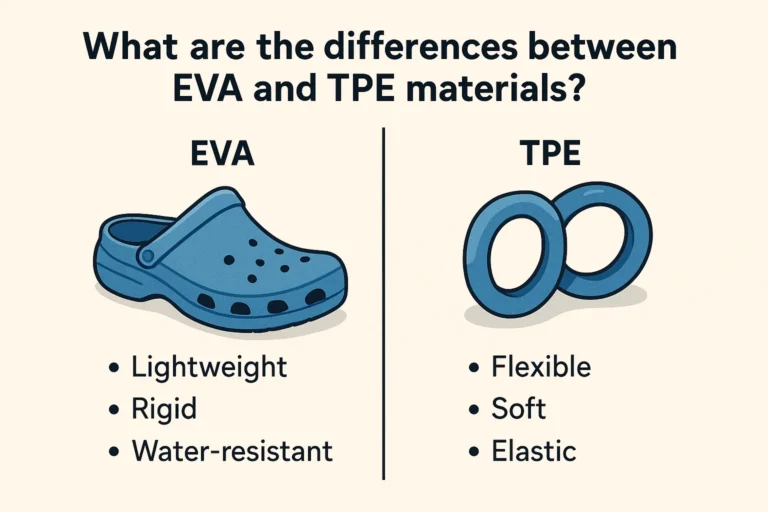

Before diving into the manufacturing process, it’s important to understand what EVA foam is. EVA is a copolymer of ethylene and vinyl acetate. The magic happens during the manufacturing process, where this polymer is expanded into a “closed-cell” foam.

This closed-cell structure is key to its most valued properties:

- Lightweight & Buoyant: The trapped gas bubbles make it incredibly light and unable to absorb water.

- Exceptional Shock Absorption: It can withstand significant impact, protecting whatever it encases.

- Flexibility & Durability: It remains flexible at low temperatures and is resistant to cracks, UV radiation, and weathering.

- Wärmedämmung: It effectively resists heat transfer.

These characteristics make it a superior choice for a vast range of applications, a topic we’ll explore further.

The EVA Foam Material Manufacture Process: A Step-by-Step Look

Creating high-quality EVA foam is a multi-stage process that demands precision, expertise, and advanced machinery. At Damao Tech, we have perfected each step to ensure consistency and excellence in every batch.

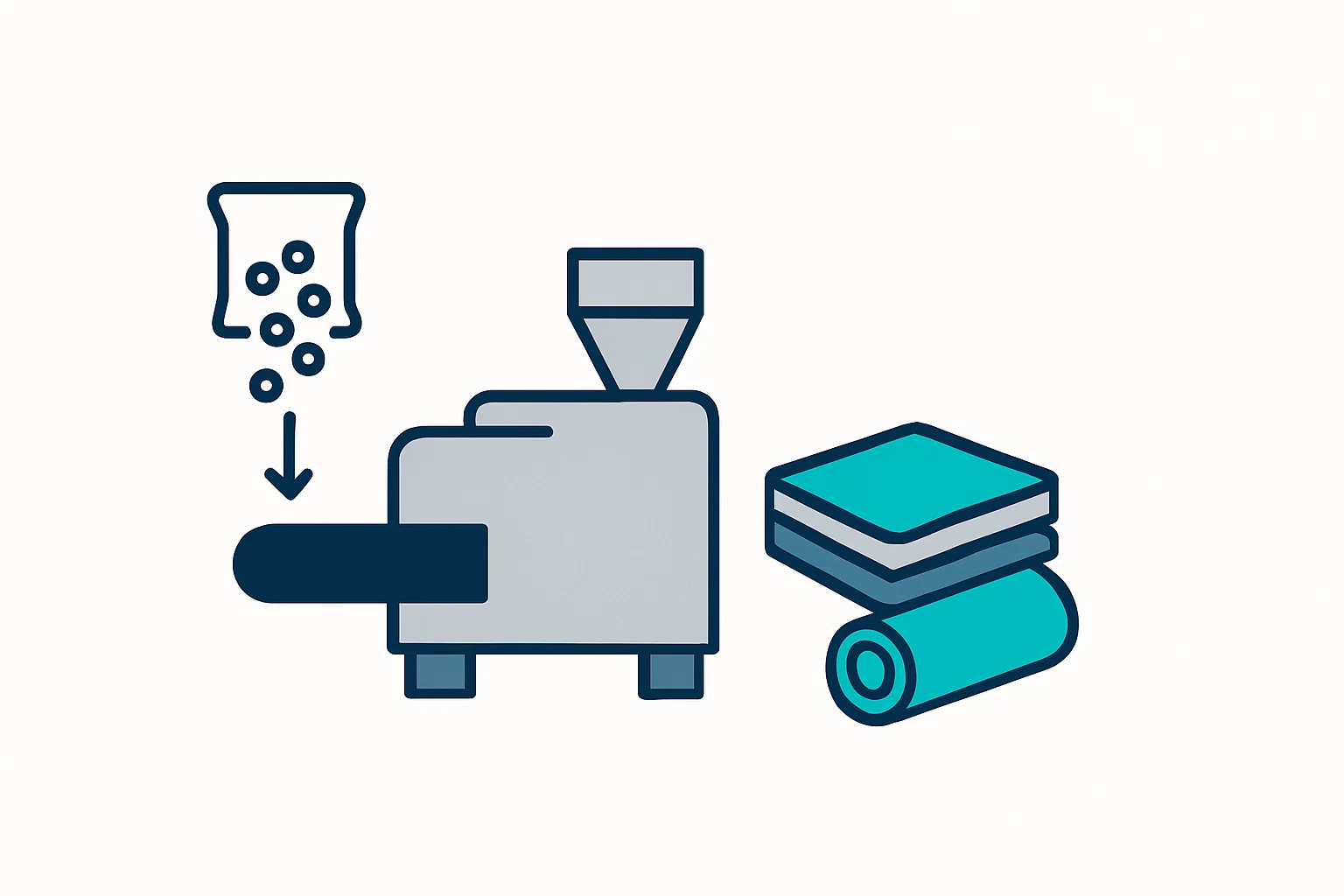

Step 1: Compounding the Raw Materials

The journey begins with a precise recipe. We start with raw EVA polymer pellets and mix them with several critical additives in a large-scale industrial blender. These additives include:

- Blowing Agents: These chemicals decompose at high temperatures to release gas (like nitrogen), which creates the foam’s cellular structure.

- Cross-linking Agents: These facilitate the formation of strong chemical bonds between polymer chains, giving the foam its durability and “memory.”

- Fillers & Pigments: Fillers can adjust the foam’s density and cost, while pigments provide the desired color.

The exact ratio of these components is a proprietary formula, tailored to achieve the specific density, hardness, and color requested by our clients.

Step 2: Kneading and Molding

Once compounded, the mixture is heated and kneaded into a homogenous, dough-like mass. This ensures all additives are evenly distributed. The molten material is then carefully transferred into large, high-pressure molds. The size of the mold determines the initial dimensions of the raw foam “bun” or block.

Step 3: Foaming and Curing

This is where the transformation occurs. The filled molds are placed into a hydraulic press that applies immense pressure and heat. The high temperature activates the blowing agent, releasing gas, and the cross-linking agent, which solidifies the polymer network. The pressure contains this expansion until the mold is opened. Upon release, the solid block expands rapidly to its final size, much like a loaf of bread rising.

Step 4: Stabilization

The freshly expanded foam bun is hot and unstable. It is carefully moved to a cooling and stabilization area for a set period. This curing process allows the foam’s internal structure to settle, ensuring its final properties—like dimension, hardness, and cell size—are stable and consistent.

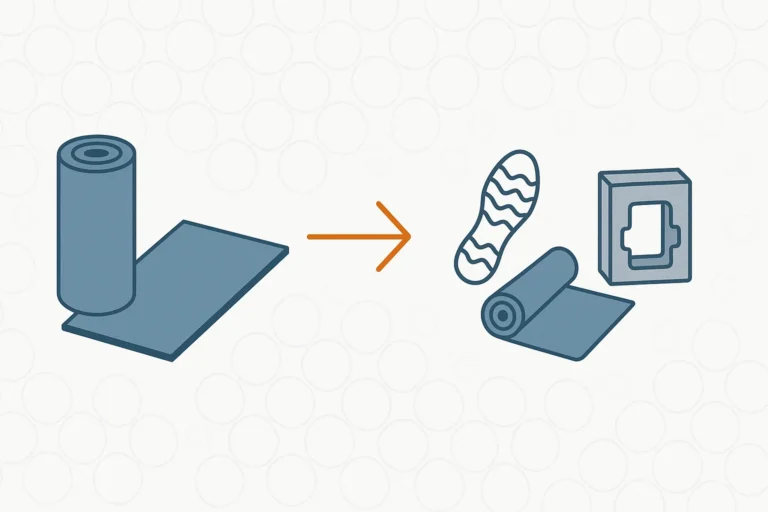

From Raw Buns to Finished Products: Damao Tech’s Capabilities

A raw foam bun is just the beginning. Damao Tech’s expertise extends to converting these large blocks into usable, application-specific formats.

- EVA Foam Panels: We use specialized skiving and splitting machines to slice the large buns into panels and sheets of precise thickness, from a few millimeters to several inches thick.

- EVA Foam Rolls: For applications requiring continuous, flexible material, we can produce EVA foam in roll form, perfect for automated production lines or large-scale laminating.

- Custom Fabricated Items: This is where our experience truly shines. Using advanced techniques like die-cutting, CNC routing, heat lamination, and adhesive backing, we can transform our comprehensive range of EVA-Schaum into custom-designed components, inserts, gaskets, and finished products tailored to your exact specifications.

Key Applications of High-Quality EVA Foam

The versatility of the EVA foam material we manufacture allows it to serve countless industries:

- Verpackung: Custom-cut inserts for tool cases, electronics, and medical equipment.

- Sport & Freizeit: Yoga mats, gym flooring, protective padding, and water sports equipment.

- Automobilindustrie: Gaskets, seals, interior trim, and NVH (noise, vibration, and harshness) components.

- Marine: Decking, buoyancy aids, and seating cushions.

- Fußbekleidung: Midsoles, insoles, and orthopedic supports.

Why Partner with Damao Tech for Your EVA Foam Needs?

Choosing the right manufacturing partner is critical. At Damao Tech, we build our reputation on the E-E-A-T principles:

- Experience: With years of hands-on experience, we understand the nuances of foam fabrication.

- Fachwissen: Our team possesses deep technical knowledge of polymer science and manufacturing technology.

- Authoritativeness: We are not just suppliers; we are solution providers who guide our clients to the best material choices for their applications.

- Trustworthiness: We are committed to rigorous quality control, on-time delivery, and transparent communication, ensuring you receive a product you can rely on.

Häufig gestellte Fragen (FAQ)

1. What is the difference between open-cell and closed-cell foam?

EVA foam is a closed-cell foam, meaning its internal cells are not interconnected. This makes it waterproof, more durable, and firmer than open-cell foams (like a kitchen sponge), which readily absorb liquid.

2. Can EVA foam be customized in terms of color, density, and hardness?

Absolutely. During the initial compounding stage of the EVA-Dämmstoff-Herstellung process, we can introduce pigments to match specific brand colors and adjust the formulation to achieve a wide range of densities (weight) and durometers (hardness).

3. Is EVA foam recyclable?

While not biodegradable, EVA foam is technically recyclable. At Damao Tech, we are committed to sustainable practices by minimizing waste during production and exploring recycling programs for post-industrial scrap.

Bereit, Ihr nächstes Projekt zu starten?

Ob Sie hochwertige EVA-Schaum Panele, vielseitige Rollen oder ein vollständig maßgefertigtes, präzisionsgebautes Bauteil benötigen, Damao Tech verfügt über die Expertise und Fertigungskapazitäten, um Ihre Vision Wirklichkeit werden zu lassen. Unser Team ist bereit, Ihre Anforderungen zu besprechen und eine Lösung zu bieten, die Ihren Leistungsfähigkeits- und Budgetbedürfnissen entspricht.

Kontaktieren Sie uns noch heute, um ein Angebot anzufordern oder mit einem unserer Schaumstoffspezialisten zu sprechen!