What are the Disadvantages of EVA Foam? An Objective Analysis

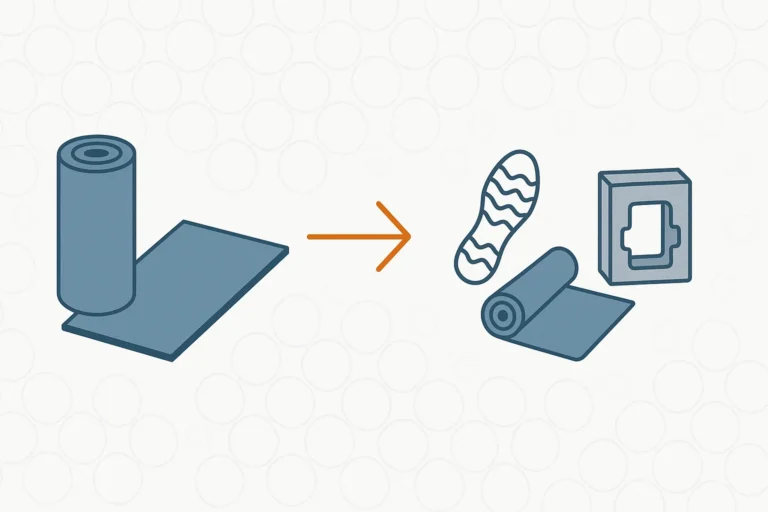

Ethylene-Vinyl Acetate (EVA) is widely celebrated for its lightweight cushioning and versatility. However, as an industry-leading manufacturer, Damao Tech believes that informed decisions require a full understanding of a material’s limitations. Recognizing the disadvantages of EVA foam is crucial for engineers and buyers to ensure product longevity and safety.

Core Limitations of EVA Foam

While EVA foam excels in many areas, certain environmental and mechanical factors can impact its performance. Here is a breakdown of the primary drawbacks:

Low Thermal Resistance

EVA foam has a relatively low melting point compared to other elastomers. In high-heat environments (exceeding 70°C/158°F), it may warp, shrink, or lose its structural integrity.

Permanent Compression

Over time and under repeated heavy loads, EVA foam can suffer from “compression set.” This means it may not fully return to its original thickness, eventually losing its cushioning properties.

Chemical Sensitivity

While resistant to water, EVA can degrade when exposed to certain oils, petroleum-based solvents, or strong chemicals. This makes it less ideal for specific industrial gaskets.

Recycling Challenges

Unlike Thermoplastic Elastomers (TPE), standard EVA foam is a cross-linked material, which makes it more difficult to melt down and recycle in traditional facilities.

How Damao Tech Mitigates These Drawbacks

Understanding these challenges is the first step toward solving them. At Damao Tech, we utilize advanced chemical engineering to offset many of these natural limitations.

| Disadvantage | Industry Impact | The Damao Tech Solution |

|---|---|---|

| Compression Set | Soles flatten over time | High-resiliency blends that increase energy return. |

| Surface Wear | Easily scratched | Custom skin-forming technology for a tougher exterior. |

| Odor (Off-gassing) | Unpleasant “new foam” smell | Vacuum-deodorizing processes to minimize VOCs. |

| Eco-Impact | Landfill waste | Integration of 20%+ GRS-certified recycled content. |

Expert Decision Guide: When Should You Look for Alternatives?

At Damao Tech, we want your project to succeed. You might consider alternatives to EVA foam if:

- High-Heat Exposure: Your product will be used in automotive engines or high-temp industrial zones (Consider Silicone or EPDM).

- Constant Heavy Loads: For heavy machinery vibration dampening (Consider high-density PU or Rubber).

- Full Circularity: If your brand requires 100% closed-loop recyclability (Consider our TPE alternatives).

Not sure if EVA is right for you? Our technical team can provide a material comparison based on your specific stress-test requirements.

Speak with a Material EngineerFrequently Asked Questions

Because Damao Tech uses closed-cell EVA foam, the material remains water-resistant even if the surface is cut. However, deep punctures can trap moisture in the gaps between the cut cells.

High-quality EVA foam is non-toxic. However, low-grade foams may contain formamides. Damao Tech ensures all products are SGS-tested and free from harmful chemicals.

Direct UV exposure and heat cause the air inside the closed cells to expand and contract. Over time, this leads to “thermal shrinkage.” We offer UV-stabilized versions to combat this effect.

While all foam eventually ages, choosing a higher-density grade from Damao Tech significantly extends the lifespan of the product compared to standard craft-grade foams.

Get the Right Material Specification Today

The “disadvantages” of a material are often just a matter of choosing the wrong specification. Damao Tech helps you match density, hardness, and additives to your specific environment.

Request a Sample & Quote