EVA Foam Sheets Technical Guide: Understanding Density, Hardness, and Quality

Whether you are an engineer designing shock-absorbing industrial pads, a footwear manufacturer looking for the perfect midsole, or a creative professional building intricate props, the success of your project hinges on one thing: selecting the right material. At Damao Tech, we understand that not all foam is created equal.

In this comprehensive guide, we dive deep into the technical specifications of EVA foam sheets, helping you navigate the complexities of density, hardness, and durability to ensure you get the exact performance your project demands.

What is EVA Foam?

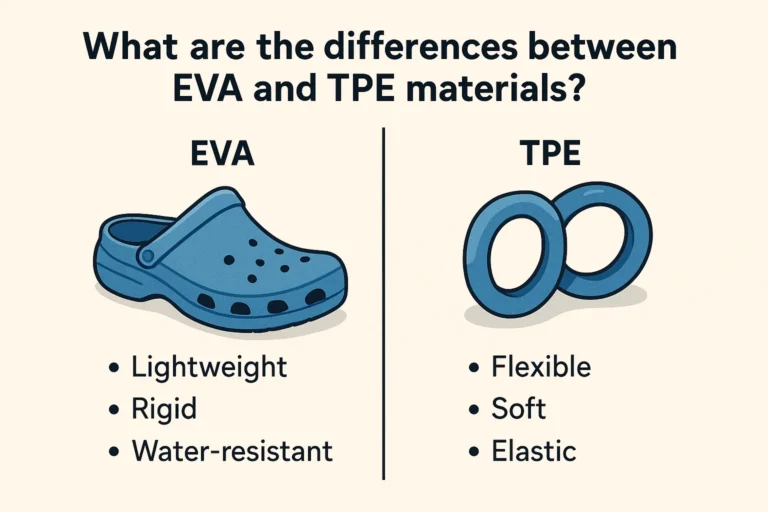

Ethylene-Vinyl Acetate (EVA) is a closed-cell copolymer foam known for its exceptional versatility. It bridges the gap between soft rubber and rigid plastics, offering a unique balance of durability, flexibility, and water resistance. However, to truly unlock its potential, you must understand the two critical metrics that define its character: Density and Hardness.

Understanding EVA Density: The Core of Durability

Density is defined as the mass of the foam per unit of volume, typically measured in kilograms per cubic meter ( kg/m ³). It is the single most important factor regarding the longevity and resilience of the material.

Why “Ultra High Density” Matters

While standard EVA foam is excellent for lightweight cushioning, ultra high density EVA foam sheets represent the pinnacle of durability. Ranging from 150 kg/m ³ to 280 kg/m ³, these high-density sheets are engineered to withstand rigorous stress without collapsing.

- Compression Resistance: Lower density foams may permanently flatten (bottom out) under heavy loads. Ultra high density options bounce back, maintaining their thickness and cushioning properties over years of use.

- Surface Finish: Higher density results in a smoother, finer cell structure. This is vital for applications requiring a pristine aesthetic or precise machining, such as laser cutting or CNC routing.

- Water & Chemical Resistance: A denser cell structure provides a superior barrier against moisture and mild chemicals, making it ideal for marine decking or industrial gaskets.

At Damao Tech, we offer a wide range of densities, recommending high-density grades for heavy-duty applications where failure is not an option.

The Hardness Spectrum: Finding the Right Balance

While density measures weight, hardness measures the material’s resistance to indentation. In the EVA industry, this is measured on the Shore A durometer scale. This spectrum typically ranges from 15 (very soft) to 80 (very hard).

Choosing the correct hardness is critical for the feel and function of your product:

1. Soft / Low Hardness (Shore A 25–35)

- Feel: Similar to a soft gel insert or a plush yoga mat.

- Application: Ideal for interior padding, helmet liners, therapeutic insoles, and costume comfort layers. It prioritizes comfort and flexibility over structural support.

2. Standard / Medium Hardness (Shore A 38–45)

- Feel: Firm but flexible, similar to a standard exercise mat or flip-flop sole.

- Application: This is the industry standard for most general-purpose applications. It offers the perfect balance between cushioning and durability, widely used in packaging inserts, gym mats, and toys.

3. Rigid / High Hardness (Shore A 60–75+)

- Feel: Hard and tough, similar to a car tire or a shoe heel.

- Application: Designed for outsoles, automotive protective bumpers, heavy-machinery vibration pads, and structural elements. It resists abrasion and holds its shape under pressure.

Customization at Damao Tech: Do you need a specific hardness, such as Shore A 55? We can customize the formulation to meet your precise technical requirements.

EVA Foam Sheets Product Info and Reviews: How to Spot Quality

When searching for eva foam sheets product info and reviews online, it can be difficult to separate marketing claims from technical reality. As industry experts, we advise looking for specific indicators of quality that we prioritize in our manufacturing process:

- Cell Uniformity: Cut a cross-section of the sheet. High-quality EVA should have uniform bubbles (cells) visible to the naked eye. Inconsistent cell sizes lead to weak spots and uneven tearing.

- Color Consistency: Professional-grade sheets should have a consistent color throughout the entire thickness, not just on the surface.

- Low Odor: Excessive chemical smell often indicates low-quality processing or residual solvents. Premium EVA foam sheets from Damao Tech are processed to minimize odor, making them safer for indoor use and consumer products.

Why Damao Tech? The Importance of Material Expertise

In the world of material supply, trust is built on consistency and technical knowledge. Damao Tech prides itself on adhering to the highest standards of quality and reliability.

- Proven Experience: Our team doesn’t just sell foam; we understand the chemical composition and mechanical properties of every sheet we produce.

- Industry Authority: We supply industries ranging from marine to medical, meaning our materials are tested in some of the harshest environments.

- Unwavering Trust: We provide transparent data sheets and honest recommendations. If a standard Shore A 38 foam works for your prototype, we will tell you. When you source EVA foam sheets from us, you are getting material capable of meeting your exact lifespan requirements.

FAQ: Common Questions About EVA Foam

Q1: What is the most common hardness for EVA foam?

The most versatile and common hardness is between Shore A 38 and 45. This range offers a good mix of cushioning and firmness for most applications.

Q2: Can I heat-form Ultra High Density EVA foam?

Yes! While it requires a slightly higher temperature than low-density foam, ultra-high-density EVA holds its shape exceptionally well after heat forming, making it perfect for complex geometries.

Q3: Is EVA foam waterproof?

Absolutely. EVA is a closed-cell foam, meaning it does not absorb water like a sponge. It is naturally resistant to mold, mildew, and rot.

Q4: How do I cut high-density EVA foam sheets?

For sheets up to 5mm, a sharp utility knife works well. For thicker or higher-hardness sheets (Shore A 60+), we recommend using a band saw or laser cutter for a clean, professional edge.

Ready to Start Your Project?

Choosing the right material is the first step toward a successful product. Whether you need the soft comfort of Shore A 30, the versatility of standard Shore A 40, or the rugged durability of ultra-high-density foam, Damao Tech is here to supply the precision and quality you deserve.

Contact us today to request a quote or speak with one of our material specialists about your specific needs. Let’s build something durable together.