EVA Foam Density & Hardness Guide: Shore A vs Shore C Explained

Selecting the correct EVA foam is not simply a matter of softness or thickness. In industrial manufacturing, footwear development, marine applications, and protective packaging, dikte En Shore hardness directly affect durability, energy return, machinability, and service life.

At Damao Tech, we manufacture EVA foam sheets and rolls with tightly controlled density and hardness ranges to support precise engineering requirements.

Density and Shore hardness are correlated but fundamentally different parameters. Density primarily affects weight, compression resistance, and structural stability, while Shore hardness measures surface resistance to indentation under a standardized load.

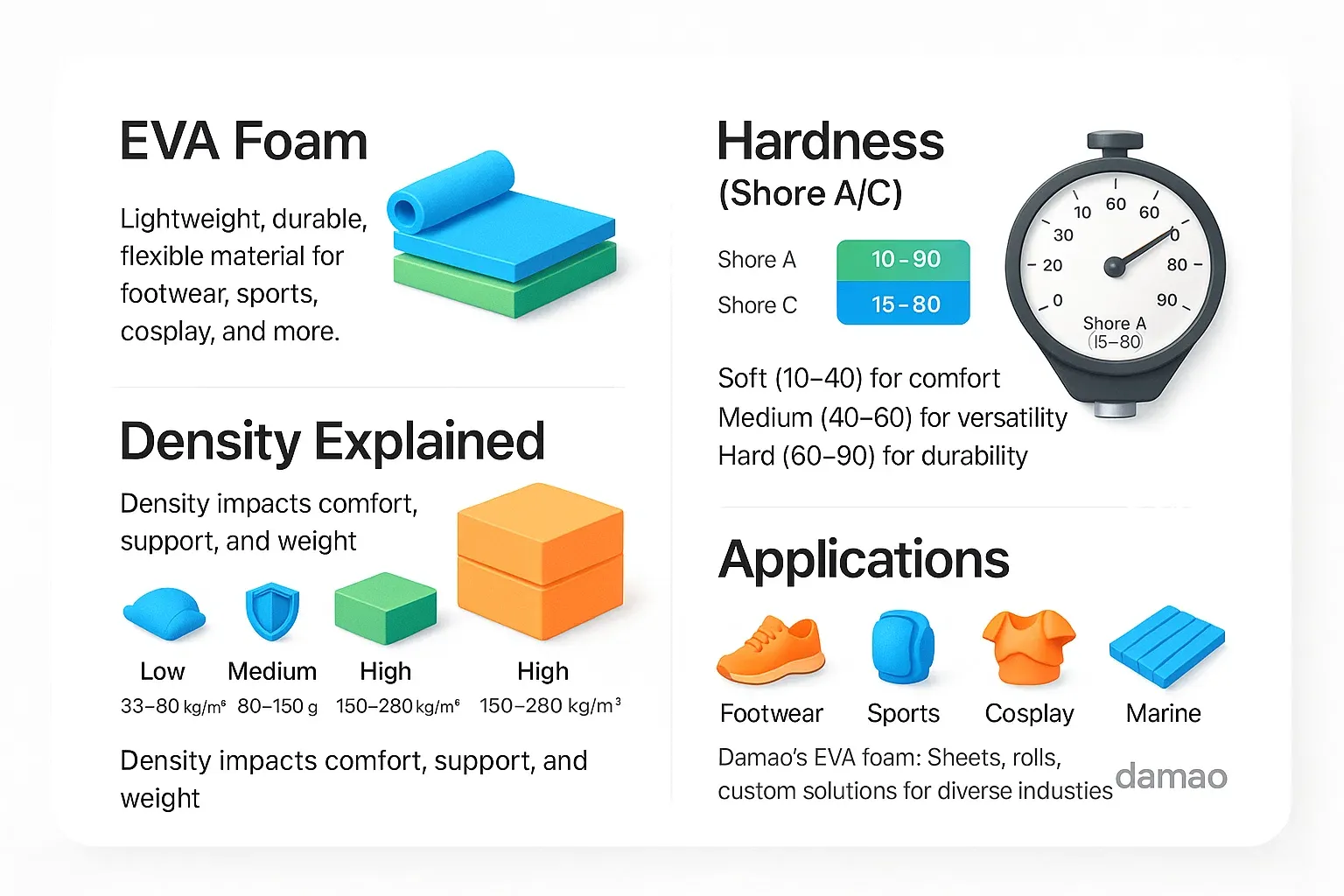

1. EVA Foam Density Classification (kg/m³)

Density determines how much material mass exists per unit volume. Higher-density EVA generally provides better load-bearing capacity, dimensional stability, and abrasion resistance, while lower-density foam prioritizes cushioning and weight reduction.

Low Density (33–80 kg/m³)

Used for yoga mats, soft protective packaging, flotation inserts, and comfort-focused cushioning where low weight and compressibility are critical.

Medium Density (80–150 kg/m³)

The most common range for athletic footwear midsoles, orthotic components, sports equipment padding, and general-purpose industrial foam parts.

High Density (150–280 kg/m³)

Preferred for marine decking, industrial gaskets, tool control foam, and applications requiring higher stiffness, wear resistance, and shape retention.

2. EVA Foam Hardness Testing Standards (Shore A & Shore C)

EVA foam hardness is commonly measured using ASTM D2240. Due to EVA’s cellular structure, different Shore scales are used depending on formulation and industry.

- Shore C: Common in footwear, sports, and foam-specific industries

- Shore A: Used when comparing EVA to rubber or elastomer components

Because Shore A and Shore C use different indenters and spring forces, there is no exact mathematical conversion between the two scales. The table below reflects commonly observed industry reference ranges.

| Shore C (EVA Foam) | Approx. Shore A | Typical Application |

|---|---|---|

| 15 – 25 C | 5 – 10 A | Extra-soft cushioning, therapeutische inlegzolen |

| 35 – 45 C | 20 – 25 A | Standaard atletische middenzolen, schokabsorberende pads |

| 55 – 65 C | 35 – 45 A | Marinehout, gereedschapscontrole foam, beschermende panelen |

| 75 – 85 C | 55 – 70 A | Rigide industriële onderdelen, structuur foam componenten |

De Shore A en Shore C waarden hierboven zijn benaderende referentieregels gebaseerd op gebruikelijke EVA foam formuleringen. Deze waarden kunnen variëren afhankelijk van dichtheid, uitbreidingsverhouding, celstructuur en testomstandigheden. Valideer altijd materiaalspecificaties met fysieke monsters.

3. Hoe Ingenieurs EVA Foam Selecteren: Een Praktische Logica

In plaats van dichtheid of hardheid in isolatie te kiezen, werken ingenieurs meestal terug van functionele vereisten:

- Rust op demping of energieabsorptie?

→ Begin met de Shore C reeks, dan pas de dichtheid aan voor duurzaamheid. - Geïnteresseerd in dimensionale stabiliteit of bewerking?

→ Begin met dichtheid, dan fine-tunen de hardheid. - Verwarmingsvorming of thermische vormgeving vereist?

→ Middel- tot hoge dichtheid met een gemiddelde Shore C verbetert de randdefinitie. - Buiten of maritieme blootstelling?

→ Hogere dichtheid en mid- tot hoge Shore C voor slijtvastheid en grip.

4. Toepassing-gebaseerde Specificatie Referentie

- Schoeisel: Laag- tot middelzware dichtheid, 20–35 Shore C voor comfort en rebound

- Marine: Hoge dichtheid, 60–65 Shore C voor UV-bestendigheid en anti-slip prestaties

- Cosplay & Props: Middel- tot hoge dichtheid, 45–70 Shore C voor hittevorming en duurzaamheid

- Beschermende Verpakking: Laag dichtheid, 35–45 Shore C voor schokabsorptie

5. Veelgestelde Vragen

Ja. Door formule en uitbreingsverhouding aan te passen, kunnen specifieke Shore hardheidswaarden worden bereikt binnen verschillende dichtheidsbereiken, binnen praktische grenzen.

V: Leveren jullie technische databladen en monsters?Ja. We leveren materiaaldatabladen en fysieke monsters voor validatie, wat sterk wordt aanbevolen voor kritieke toepassingen.

Heeft u Engineering-Level EVA Foam Ondersteuning nodig?

Vraag technische databladen, Shore hardheid monsters, of toepassingsspecifieke aanbevelingen van ons materiaalteam aan.

Neem Contact Op voor Technische Ondersteuning