Veelzijdigheid ontsluiten: Een overzicht van de vervaardiging van EVA-schuim op maat

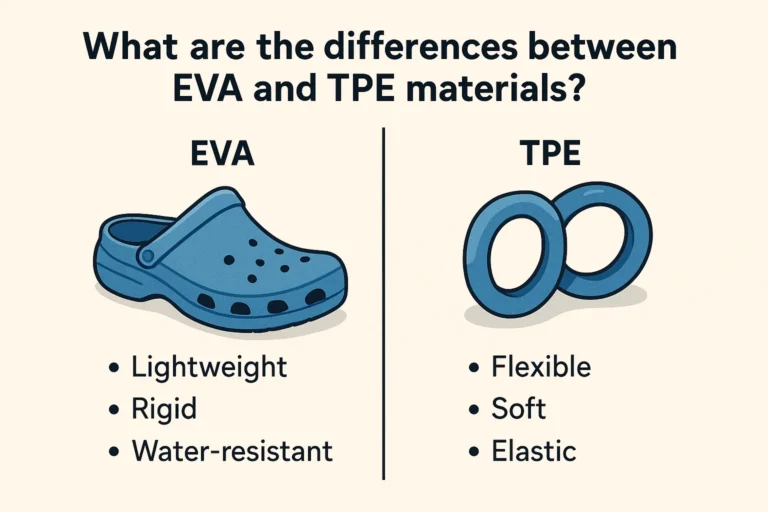

Ethyleenvinylacetaat, beter bekend als EVA-schuim, is een opmerkelijk veelzijdig en flexibel materiaal. De unieke combinatie van eigenschappen - lichtgewicht, duurzaam, schokabsorberend en waterbestendig - heeft het tot een populaire keuze gemaakt in een groot aantal industrieën. Hoewel standaard EVA-schuim vellen en spoelen een fantastisch uitgangspunt vormen, wordt het ware potentieel van dit materiaal vaak gerealiseerd door fabricage op maat.

Bij [Uw Bedrijfsnaam] zijn we gespecialiseerd in het transformeren van ruw EVA schuim in nauwkeurige, toepassingsspecifieke oplossingen. Dit artikel geeft een uitgebreid overzicht van de dienstverlening op het gebied van het vervaardigen van EVA-schuim op maat, waarbij de processen, voordelen en toepassingen worden besproken die EVA-schuim tot een onmisbare bron maken voor bedrijven die op zoek zijn naar hoogwaardige, op maat gemaakte componenten.

Wat is EVA-schuim precies?

Laten we, voordat we ons gaan verdiepen in de fabricage, even kort terugkomen op wat EVA-schuim zo speciaal maakt. EVA is een copolymeer van ethyleen en vinylacetaat. Door het percentage vinylacetaat en het productieproces te variëren, kunnen verschillende dichtheden, flexibiliteit en andere eigenschappen worden bereikt.

Belangrijkste eigenschappen van EVA-schuim:

- Lichtgewicht: Gemakkelijk te hanteren en te verwerken in producten zonder veel gewicht toe te voegen.

- Uitstekende schokabsorptie: Biedt superieure demping en schokbescherming.

- Flexibiliteit en veerkracht: Kan worden gebogen en gebogen, en terugkeren naar zijn oorspronkelijke vorm.

- Water- en chemische weerstand: Niet-poreus, dus ideaal voor maritieme, buiten- en industriële toepassingen.

- Thermische isolatie: Biedt goede isolatie tegen hitte en kou.

- Niet-giftig: Veilig voor een groot aantal toepassingen, inclusief toepassingen met huidcontact.

- Drijfvermogen: Door de gesloten celstructuur drijft het van nature.

- Duurzaamheid: Bestand tegen scheuren en UV-degradatie (afhankelijk van de kwaliteit).

Deze eigenschappen maken EVA-schuim een ideale kandidaat voor maatwerk, waardoor we oplossingen op maat kunnen maken voor zeer specifieke behoeften.

Het fabricageproces van EVA-schuim op maat: Van concept tot onderdeel

De productie van EVA-schuim op maat is een meerfasenproces dat is ontworpen om uw ideeën of vereisten om te zetten in tastbare, afgewerkte producten van hoge kwaliteit.

1. Overleg en ontwerp:

De reis begint met het begrijpen van je specifieke behoeften. Dit houdt in:

* De beoogde toepassing en prestatievereisten bespreken.

* Bestaande ontwerpen beoordelen of nieuwe ontwerpen ontwikkelen met behulp van CAD-software (Computer-Aided Design).

* Rekening houden met omgevingsfactoren, esthetische voorkeuren en budgetbeperkingen.

2. Materiaalkeuze:

Het juiste type EVA-schuim kiezen is cruciaal. Wij helpen je bij het selecteren:

* Dichtheid: Van zacht en buigzaam tot stevig en stijf.

* Dikte: Verkrijgbaar in een breed assortiment om te voldoen aan verschillende dempings- of structuurbehoeften.

* Kleur: Er is een breed spectrum aan kleuren beschikbaar voor branding of functionele codering.

* Speciale eigenschappen: Antistatische, vlamvertragende of geleidende opties indien nodig.

Onze uitgebreide voorraad van EVA-schuim vellen en spoelen zorgt ervoor dat we het juiste basismateriaal voor je project hebben.

3. Fabricagetechnieken:

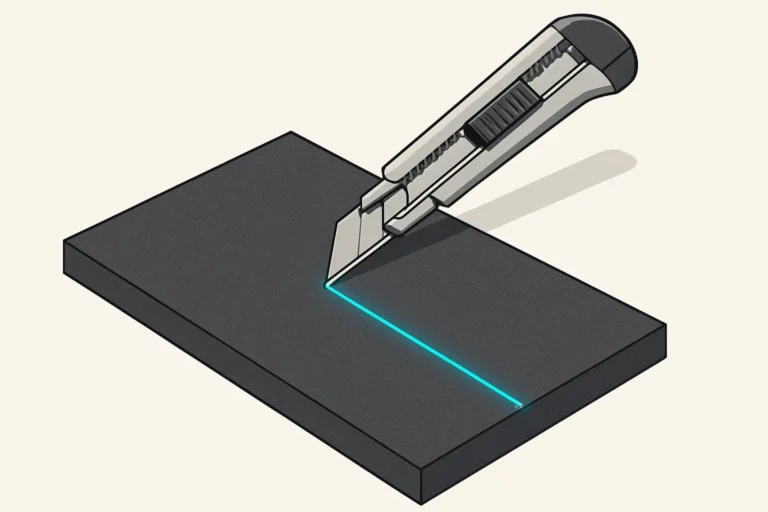

Hier wordt het ruwe EVA-schuim gevormd en getransformeerd. Gebruikelijke technieken zijn onder andere:

* **Die Cutting:** Ideaal voor de productie van grote volumes consistente, relatief eenvoudige vormen. Een op maat gemaakte stalen matrijs drukt door het EVA-schuim.

*Pros:* Snel, kosteneffectief voor grote series, nauwkeurig.

*Cons:* Voorafgaande gereedschapskosten, minder geschikt voor ingewikkelde ontwerpen of kleine series.

* **CNC Frezen/Snijden:** Een computergestuurde router of mes snijdt complexe vormen, patronen en zelfs 3D contouren met hoge precisie.

* Voordelen:* Uitstekend geschikt voor ingewikkelde ontwerpen, prototypes en kleine tot middelgrote series. Geen harde gereedschapskosten.

*Cons:* Kan langzamer zijn dan stansen voor zeer grote volumes.

* Lasersnijden:** Gebruikt een gefocuste laserstraal om EVA-schuim met uiterste precisie te snijden of te graveren.

* Voordelen:* Zeer hoge precisie voor ingewikkelde details, schone randen, geschikt voor prototyping.

*Cons:* Kan langzamer zijn voor dikke materialen, kan een lichte geur of verkleuring aan de randen veroorzaken bij sommige EVA-types.

* **Waterstraalsnijden:** Een waterstraal onder hoge druk (soms gemengd met een schuurmiddel) snijdt door het schuim.

*Pros:* Snijdt dikke materialen schoon, geen warmte-beïnvloede zones, complexe vormen.

*Cons:* Kan een langzamer en duurder proces zijn.

* **Thermoforming/Moulding:** EVA-schuimplaten worden verwarmd tot ze buigzaam zijn en vervolgens over of in een mal gevormd om driedimensionale vormen te creëren.

* Voordelen:* Creëert complexe 3D-onderdelen, goed voor items zoals vulling, inzetstukken en koffers.

*Cons:* Vereist gereedschap (mallen).

*Lamineren & Hechten:** Meerdere lagen EVA-schuim (of EVA-schuim met andere materialen zoals stof, kunststof of lijm) kunnen aan elkaar worden gehecht om specifieke diktes, kleuren of functionele eigenschappen te verkrijgen.

* **Skiving & Splitting:** Precies de dikte van EVA-schuimplaten verminderen of ze in dunnere lagen verdelen.4. Afwerking en montage:

Eenmaal gefabriceerd, kunnen onderdelen verdere afwerkingsprocessen ondergaan:

* Randafwerking: Randen gladmaken of afronden.

* Afdrukken/embossing: Logo's, branding of instructies toevoegen.

* Montage: Meerdere EVA-schuimonderdelen combineren of integreren met andere onderdelen.

* Lijmtoepassing: Drukgevoelige kleefmiddelen (PSA's) aanbrengen voor eenvoudige installatie.

5. Kwaliteitscontrole:

Tijdens het hele proces zorgen strenge kwaliteitscontroles ervoor dat elk onderdeel voldoet aan de overeengekomen specificaties voor afmetingen, materiaaleigenschappen en algemene afwerking.

Toepassingen van Oplossingen van het Schuim van EVA van de Douane

De veelzijdigheid van op maat gemaakt EVA-schuim betekent dat het toepassingen vindt in een groot aantal sectoren:

- Verpakking: Beschermende inzetstukken voor kwetsbare apparatuur, elektronica en gereedschap.

- Sport en vrije tijd: Vulling voor helmen en beschermende kleding, yogamatten, drijfhulpmiddelen, bootdekken.

- Automobiel: Pakkingen, afdichtingen, interieurbekleding, antiratelonderdelen, voeringen voor gereedschapsladen.

- Marine: Vlonders, zitkussens, spatbordonderdelen, drijfvermogen.

- Medisch & Gezondheidszorg: Orthesesteunen, prothesevullingen, positioneringshulpmiddelen, inzetstukken voor medische hulpmiddelen.

- Elektronica: Antistatische verpakking, demping voor gevoelige onderdelen, pakkingen.

- Bouw: Uitzettingsvoegen, isolatie, vloerbedekking.

- Kunst, ambacht en Cosplay: Gemakkelijk te snijden en te vormen voor rekwisieten, kostuums en modellen.

- Promotionele producten: Custom sleutelhangers, muismatten en andere merkartikelen.

Ons vermogen om toepassingsspecifieke oplossingen te bieden, betekent dat we EVA schuimproducten precies kunnen afstemmen op de eisen van deze uiteenlopende industrieën en nog veel meer.

Voordelen van het Kiezen van Aangepaste EVA Schuim Fabricage

Kiezen voor op maat gemaakte EVA-schuimcomponenten in plaats van kant-en-klare oplossingen biedt aanzienlijke voordelen:

- Nauwkeurige pasvorm en functie: Componenten worden ontworpen en gefabriceerd volgens exacte specificaties, voor een perfecte integratie en optimale prestaties binnen uw product of systeem.

- Geoptimaliseerde prestaties: De materiaaleigenschappen (dichtheid, dikte, enz.) worden specifiek geselecteerd voor de toepassing, om duurzaamheid, bescherming of comfort te verbeteren.

- Kosteneffectiviteit op de lange termijn: Hoewel er sprake kan zijn van initiële ontwerp- of gereedschapskosten, leidt maatwerk vaak tot minder materiaalverspilling, snellere assemblagetijden en een langere levensduur van het product, wat een betere algemene waarde oplevert.

- Verbeterde merkidentiteit: Aangepaste kleuren, logo's in reliëf en unieke vormen kunnen je merk versterken en je producten onderscheiden.

- Materiaalefficiëntie: Precisiefabricage minimaliseert afval en sluit aan bij duurzame productiepraktijken. Deze focus op efficiëntie is een kernwaarde die we delen en die voortkomt uit onze expertise in het leveren van oplossingen die het gebruik van hulpbronnen optimaliseren.

- Geconsolideerde toeleveringsketen: Samenwerken met één partner voor zowel de levering van grondstoffen (zoals onze EVA-schuim vellen en spoelen) en fabricage op maat vereenvoudigt de inkoop en het projectbeheer.

| Functie | Stansen | CNC Frezen/Snijden |

|---|---|---|

| Beste voor | Hoog volume, eenvoudige vormen | Prototypes, complexe vormen, klein-medisch volume |

| Kosten gereedschap | Hoger (aangepaste matrijs) | Lager (geen hard gereedschap) |

| Kosten per eenheid | Lager (bij hoog volume) | Hoger (bij hoog volume) |

| Doorlooptijd | Langer (voor gereedschap) | Korter (voor installatie) |

| Ontwerp Flex. | Lager Hoger

Waarom samenwerken met [Uw bedrijfsnaam] voor uw EVA-schuimbehoeften?

Bij [Uw bedrijfsnaam] combineren we diepgaande materiaalkennis met geavanceerde productiemogelijkheden om superieure oplossingen op maat van EVA-schuim te leveren. We begrijpen dat elk project uniek is en we zetten ons in om:

- Technische expertise: Ons team heeft een grondige kennis van de eigenschappen en fabricageprocessen van EVA-schuim, zodat u verzekerd bent van het beste advies en de beste resultaten.

- Uitgebreid productassortiment: Van de inkoop van hoogwaardige EVA-schuim vellen en spoelen tot het leveren van ingewikkelde op maat gemaakte producten, bieden we een end-to-end service.

- Kwaliteitsborging: We houden ons in elk stadium aan strenge kwaliteitscontrolemaatregelen, zodat we kunnen garanderen dat onze componenten precies aan uw eisen voldoen.

- Gezamenlijke aanpak: We werken nauw met je samen van concept tot oplevering en zorgen ervoor dat je visie effectief en efficiënt wordt gerealiseerd.

- Focus op toepassingsspecifieke oplossingen: We snijden niet alleen schuim, we ontwikkelen oplossingen die uw specifieke uitdagingen oplossen en uw producten verbeteren.

Onze achtergrond in het leveren van robuuste en efficiënte machineoplossingen (zelfs als het gaat om recycling, vertaalt het principe van efficiëntie en robuuste techniek zich) vormt de basis van onze benadering van fabricage - we streven naar precisie, duurzaamheid en optimaal materiaalgebruik in elk project van EVA-schuim op maat.

Conclusie: Uw Partner in de Innovatie van het Schuim EVA van de Douane

De productie van EVA-schuim op maat opent een wereld van mogelijkheden voor het creëren van op maat gemaakte onderdelen die superieure prestaties, bescherming en esthetiek bieden. Of u nu ingewikkelde inzetstukken, duurzame vulling, gespecialiseerde pakkingen of unieke merkartikelen nodig hebt, door gebruik te maken van deskundige productiediensten kan standaard EVA-schuim worden getransformeerd tot een hoogwaardige aanwinst voor uw bedrijf.

Als u wilt onderzoeken hoe EVA-schuim op maat uw producten of projecten ten goede kan komen, nodigen wij u uit om Neem contact met ons op om uw wensen met onze specialisten te bespreken. Laat Your Company uw betrouwbare partner zijn in het benutten van het volledige potentieel van EVA-schuim.